| Author |

Message |

|

Richard Chapman

Location: Auburn, AL Joined: 14 Jan 2004

Posts: 17

|

Posted: Mon 19 Apr, 2004 8:53 am Post subject: How to sharpen a sword? Posted: Mon 19 Apr, 2004 8:53 am Post subject: How to sharpen a sword? |

|

|

I read the recent topic about how you are unlikely to be successful sharpening

a sword that was meant to be used without an edge (e.g. reenactment, martial arts practice). But,

suppose I have a sharp one, and it has just gotten dull over time from use -- too

many 2-litre bottles, say. How do you go about sharpening it? I have a ton of stones:

Arkansas, Japanese water stones, oil stones, diamond stones, etc. But I have

never used them on a blade longer than about 7". How do you hold the sword?

Where do you put the stone, etc? I can't think of a good way to do this.

The only long blade I ever sharpened was a lawn mower blade: I put it down on a stair step

hanging off the edge, put my foot on the other end and used a bastard mill file to sharpen it, both

hands on the file, one at each end. I don't want to put my foot on the sword blade, but

somehow holding the blade steady and moving the stone seems right. Use a vise? Any

advice would be welcome.

Finally, would the process be different for a differentially tempered katana (PPK)

versus a straight medieval sword (say Albion or ATrim) versus a cavalry sabre?

Thanks,

RIchard Chapman

|

|

|

|

William Goodwin

|

Posted: Mon 19 Apr, 2004 10:15 am Post subject: Posted: Mon 19 Apr, 2004 10:15 am Post subject: |

|

|

Hi ya Richard,

What I"ve started to do lately is take my 10" oil stone, c-clamp it to the edge of my work table so that it hangs over the edge (forms a "T" shape with the table being the horizontal line)and then move the sword along the stone instead of vice versa. Wear some leather gloves while doing this or anyway of sharpening. The reason I started doing it this way is that I got tried of slicing my knuckles & hands up moving the stone along the blade,plus it seems to give better control of the over-all edge.

Just my way, I'm sure others have their own.

William

aka Bill

|

|

|

|

|

Jason M. K.

Location: Maryland Joined: 25 Jan 2004

Posts: 6

|

Posted: Mon 19 Apr, 2004 3:31 pm Post subject: Posted: Mon 19 Apr, 2004 3:31 pm Post subject: |

|

|

What are the stones you are describing?

Jason M. K.

|

|

|

|

|

Richard Chapman

Location: Auburn, AL Joined: 14 Jan 2004

Posts: 17

|

Posted: Tue 20 Apr, 2004 10:38 am Post subject: Posted: Tue 20 Apr, 2004 10:38 am Post subject: |

|

|

| Jason M. K. wrote: | What are the stones you are describing?

Jason M. K. |

You mean the stones I've used for knives? I've "hard" and "soft" Arkansas stones that I

use with honing oil on pocket knives, Japanese water stones in a variety of grits: 600,1000,

2000,4000,8000 that I use on Japanese kitchen knives and straight razors, Spyderco

sharpmaker ceramic sharpening rods that I use on straight knives, and a diamond-impregnated

thing that is very good for reshaping (broken tips, nicks, etc) which I would guess is in the

200-400 grit range. I had no idea if any of them are suitable for swords.

-Richard

|

|

|

|

|

Dave Hahn

Location: Toronto, Canada Joined: 23 Aug 2003

Posts: 80

|

Posted: Thu 22 Apr, 2004 9:13 am Post subject: Posted: Thu 22 Apr, 2004 9:13 am Post subject: |

|

|

if you want a really good edge, i would suggest doing it by hand with a sanding block. cover that sanding block in foam or rubber, than place sand paper on it and do the various grit type business.

you should be able to put a great convex edge to it.

takes time, but the results are worth it.

Try not to take yourself too seriously.

|

|

|

|

Sean Flynt

|

|

|

|

|

Anders Würtz

Location: Aarhus, Denmark Joined: 11 Jan 2006

Posts: 1

|

Posted: Wed 11 Jan, 2006 12:15 pm Post subject: My sword Posted: Wed 11 Jan, 2006 12:15 pm Post subject: My sword |

|

|

I have a bastardsword made by Jiří Kronďák (http://www.fabri-armorum.cz/angl_uvod.htm).

It has an edge of about 1.5-2 mm, and I want it sharp.

Should I take it up to the local sharpener, or should I use my own grind-stone?

It has to be said, that if I walk up to the local sharpener, it is the "ghetto" and I would look like a bad guy...

Is it worth a try to ask the sharpener?[/url]

|

|

|

|

Craig Peters

|

Posted: Wed 11 Jan, 2006 12:23 pm Post subject: Posted: Wed 11 Jan, 2006 12:23 pm Post subject: |

|

|

Richard,

I believe there's a short article by Peter Johnsson about sharpening swords in the back of David Lindholm's translation of Ringeck, Sigmund Ringeck's Knightly Art of the Longsword. I would recommend getting ordering this book; I have been meaning to do so myself.

Alternatively, Peter might just explain how to do it here in the forums.

|

|

|

|

Greyson Brown

|

Posted: Wed 11 Jan, 2006 1:00 pm Post subject: Posted: Wed 11 Jan, 2006 1:00 pm Post subject: |

|

|

I haven't tried to sharpen a sword that came sharp (i.e Albion), but while I was on leave, I sharpened several Windlass pieces that did not originally have sharp edges. I found the best way to do this was clamp it in a vise and use a stand to support the tip (if tou don;t have these, using William goodwin's C-clamp method should work), and then draw filing the edge.

If you are not familiar with draw filing, that is where you hold the file perpendicular to the dege of the blade, and pull it straight towards you (you could push away, but I find I have less control doing that). I have had good luck sharpening blades and keeping a fairly even bevel using this method.

One note: orienting the file so that it cuts has meant having the handle on the right with all of the files that I have used, but you might want to double check before you get carried away wasting energy and doing nothing.

One warning: this method will create a secondary edge bevel. If you want to aviod that, you will have to use more patience, and one of the methods described by either William, Dave, and Sean.

-Grey

"So long as I can keep the path of honor I am well content."

-Sir Arthur Conan Doyle, The White Company

|

|

|

|

M. Taylor

Location: Chesterland, Ohio Joined: 01 Mar 2004

Posts: 128

|

Posted: Wed 11 Jan, 2006 6:02 pm Post subject: Posted: Wed 11 Jan, 2006 6:02 pm Post subject: |

|

|

| Dave Hahn wrote: | if you want a really good edge, i would suggest doing it by hand with a sanding block. cover that sanding block in foam or rubber, than place sand paper on it and do the various grit type business.

you should be able to put a great convex edge to it.

takes time, but the results are worth it. |

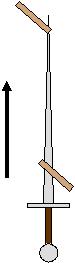

This is the method that Craig Johnson of A&A recommended to me. His suggestion was to hold the block at a 45° angle to the sword’s length and at an elevation of 22 - 25°. As you move the block down the length of the sword, you also move the block out away from the sword keeping the 45° angle of the block as you go. It will look something like the attachment below. Sorry the drawing is so crude. I blew out my back over Christmas vacation and I can't sit long in this chair.

Attachment: 3.67 KB Attachment: 3.67 KB

"Only people not able to grow tall from their own efforts and achievements seek to subdue their fellow man."

"Only people not being able to find comfort in their own mind seek to silence others. " - Per Bylund

Last edited by M. Taylor on Sat 14 Jan, 2006 12:56 pm; edited 1 time in total

|

|

|

|

|

Angus Trim

|

Posted: Wed 11 Jan, 2006 8:20 pm Post subject: Posted: Wed 11 Jan, 2006 8:20 pm Post subject: |

|

|

| Sean Flynt wrote: | War Eagle! ('87 Auburn High School alumnus / AU family).

I use a file on my Windlass pieces, followed by a cheap stone. Then, on the flats, fine sandpaper over a sanding sponge and then some steel wool (the sanding and wool just to polish out the inevitable scratches). Puts a sufficient edge on the typical Windlass/MRL blade. |

Files don't always work on AT's. Depends on the file, and or the individual sword. Quite often though, the sword blade is nearly as hard as the file......

If you have the best quality files you should be ok, but I don't recommend trying to use a file on an AT.

swords are fun

|

|

|

|

|

Angus Trim

|

Posted: Wed 11 Jan, 2006 8:25 pm Post subject: Re: How to sharpen a sword? Posted: Wed 11 Jan, 2006 8:25 pm Post subject: Re: How to sharpen a sword? |

|

|

| Richard Chapman wrote: | I read the recent topic about how you are unlikely to be successful sharpening

a sword that was meant to be used without an edge (e.g. reenactment, martial arts practice). But,

suppose I have a sharp one, and it has just gotten dull over time from use -- too

many 2-litre bottles, say. How do you go about sharpening it? I have a ton of stones:

Arkansas, Japanese water stones, oil stones, diamond stones, etc. But I have

never used them on a blade longer than about 7". How do you hold the sword?

Where do you put the stone, etc? I can't think of a good way to do this.

The only long blade I ever sharpened was a lawn mower blade: I put it down on a stair step

hanging off the edge, put my foot on the other end and used a bastard mill file to sharpen it, both

hands on the file, one at each end. I don't want to put my foot on the sword blade, but

somehow holding the blade steady and moving the stone seems right. Use a vise? Any

advice would be welcome.

Finally, would the process be different for a differentially tempered katana (PPK)

versus a straight medieval sword (say Albion or ATrim) versus a cavalry sabre?

Thanks,

RIchard Chapman |

Its been said that an expensive kat should always be sharpened by a trained polisher, though the less expensive kats can be sharpened by the owner.......

I have begun to look at euro swords the same way. Sharpening a sword can change the finish, and if the sword is actually meant to be more decoration than cutting tool, then I'd go back to the maker and see if he/ they wouldn't resharpen it for you. That way the finish should be blended back in, good as new.....

If you're just resharpening a user {Del Tin, AT, Albion Next Gen}, I used to have a lot of success with a flat diamond hone. It works fast, does a superb job. Does take some attention keeping the hone right on the edge angle, over some 30 inches of blade....... But it looks good, and you can get the edge as sharp as it can be done..........

swords are fun

|

|

|

|

|

Angus Trim

|

Posted: Wed 11 Jan, 2006 8:34 pm Post subject: Posted: Wed 11 Jan, 2006 8:34 pm Post subject: |

|

|

| Greyson Brown wrote: | I haven't tried to sharpen a sword that came sharp (i.e Albion), but while I was on leave, I sharpened several Windlass pieces that did not originally have sharp edges. I found the best way to do this was clamp it in a vise and use a stand to support the tip (if tou don;t have these, using William goodwin's C-clamp method should work), and then draw filing the edge.

If you are not familiar with draw filing, that is where you hold the file perpendicular to the dege of the blade, and pull it straight towards you (you could push away, but I find I have less control doing that). I have had good luck sharpening blades and keeping a fairly even bevel using this method.

One note: orienting the file so that it cuts has meant having the handle on the right with all of the files that I have used, but you might want to double check before you get carried away wasting energy and doing nothing.

One warning: this method will create a secondary edge bevel. If you want to aviod that, you will have to use more patience, and one of the methods described by either William, Dave, and Sean.

-Grey |

WS sword blades are generally 45 to 47 rc at the edges {I've seen softer, but not harder, though the last one I checked was two years ago}. So a good file would work well. Del Tins used to be 50rc {back when I was collecting them, but that was some years back}, and at that time, a file would be a bunch of work.......

I don't know that I would use a file on any Albion sword. Mainly an aesthetic consideration in my view, I don't really like the way a file leaves the finish. Albions come sharp, so something like a diamond hone should work well. Actually have done it once or twice here at the shop at a cutting party......

There are some used ATs out there that were never sharpened. I believe Thomas McDonald once sharpened one with a file, so if you have the right file, it can be done. But I've had shop files just skip and shriek going down the edge...... A diamond hone {once again} works well at restoring the sharpness though if the blade was sharp to start with...

swords are fun

|

|

|

|

Greyson Brown

|

Posted: Thu 12 Jan, 2006 2:51 am Post subject: Posted: Thu 12 Jan, 2006 2:51 am Post subject: |

|

|

I don't think I would recommend a file for an Albion, either. Files, for the most part, are for when you need to remove a fairly decent amount of material, and that is not what you need with a sword that is already sharp. I used a file for several Windlass/MRL swords and a Deepeeka dagger (which is even softer), but I would stick with some kind of stone, hone, or sand paper for retouching an previously sharpened sword.

-Grey

"So long as I can keep the path of honor I am well content."

-Sir Arthur Conan Doyle, The White Company

|

|

|

|

Jean Thibodeau

|

Posted: Thu 12 Jan, 2006 9:26 am Post subject: Posted: Thu 12 Jan, 2006 9:26 am Post subject: |

|

|

Well a recent production Windlass Anelace from MRL is too hard for a file to bite very much or at all.

I have gotten it almost sharp over 90% of the length of the blade with a diamond hone: Slow work since the original edge was at least 1.5 mm thick.

On the other hand the MRL chopper was easy to sharpen with a file. I also polish the edge with the diamond hone to get rid of the rough finish left by the file.

With an Albion that needs only a little refreshing of the edge I might use the diamond hone for a few light passes followed by a white extra fine ceramic hone and a final pass with a smooth hardened steel to burnish the edge and blend in with the finish. Oh, very light honing to avoid as much as possible creating an obvious secondary bevel.

You can easily give up your freedom. You have to fight hard to get it back!

|

|

|

|

William J Welch

|

Posted: Thu 12 Jan, 2006 11:23 am Post subject: sword sharpening Posted: Thu 12 Jan, 2006 11:23 am Post subject: sword sharpening |

|

|

I have found that you can take a couple of c clamps, a fine grit sandpaper, a paint stirring stick, and foam pad like what you get at a garden center.

take a portable work bench, coffee table, kitchen table, etc., and lay the foam on the end where the foam is supported by the bench, put your sand paper on it. Then lay your paint stick across the end of the foam, so the sand paper is sandwiched between the two.

Then c clamp it on each end of the paint stick, to the table edge.

When you draw a blade down the paper the foam gives and helps to keep the apple seed edge, and doesn't make you edge too flat.

William J Welch

Brotherhood of St Luke.

|

|

|

|

|

Mark Eskra

Location: Hillsboro Illinois Joined: 14 Jun 2006

Posts: 37

|

Posted: Wed 14 Jun, 2006 12:59 pm Post subject: power strop Posted: Wed 14 Jun, 2006 12:59 pm Post subject: power strop |

|

|

|

Hullo! Been there before. Remember, it's only the business end (last 12") that needs to be sharpened. I use a hard contact leather wheel to do my edges. Remember, the thinner the edge, the deeper the notch when you bash ol' iron noggin.

|

|

|

|

|

Alan B

|

Posted: Thu 27 Jul, 2006 5:02 am Post subject: Posted: Thu 27 Jul, 2006 5:02 am Post subject: |

|

|

How would i go about sharpening this kind of sword? My brother decided to be, well, your typical brother really, and blunted it whilst i was out of the house. I cannot afford for it to be professionally sharpened, and even if i could that wouldn't help, because i know of nobody with the proper equipment to do it.

What equipment would i need to sharpen it? And how would i do it as to ensure i didn't end up hurting myself? (I wish to still be able to hold it once it's done  ) )

|

|

|

|

Lancelot Chan

Industry Professional

|

Posted: Thu 27 Jul, 2006 11:32 am Post subject: Posted: Thu 27 Jul, 2006 11:32 am Post subject: |

|

|

I guess I'm the only crazy guy who hold the sword's blade by hand in half-swording way, pointing the tip upward (sometimes towards my eyes) and observe every stroke's angle with the carbondium and diamond hone..... I sharpen sword with both hands so that each of them can rest while the other was in work. Also, since my eye sight is very close to the edgeline, I can adjust the angle of sharpening in detail with my needs. I'm not suggesting anybody to follow this instruction though. :P

Ancient Combat Association —http://www.acahk.org

Realistic Sparring Weapons — http://www.rsw.com.hk

Nightstalkers — http://www.nightstalkers.com.hk

|

|

|

|

Craig Peters

|

Posted: Thu 27 Jul, 2006 12:41 pm Post subject: Posted: Thu 27 Jul, 2006 12:41 pm Post subject: |

|

|

| Alan B wrote: | How would i go about sharpening this kind of sword? My brother decided to be, well, your typical brother really, and blunted it whilst i was out of the house. I cannot afford for it to be professionally sharpened, and even if i could that wouldn't help, because i know of nobody with the proper equipment to do it.

What equipment would i need to sharpen it? And how would i do it as to ensure i didn't end up hurting myself? (I wish to still be able to hold it once it's done  ) ) |

Alan,

Assuming that sword you have is a katana, I've heard that you actually don't sharpen them, but rather have them polished. I could be totally wrong since Asian swords are not at all an area I know much about, but that's what I've heard.

|

|

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

All contents © Copyright 2003-2024 myArmoury.com — All rights reserved

Discussion forums powered by phpBB © The phpBB Group

Switch to the Basic Low-bandwidth Version of the forum

|