Native Way is a primitive weapon and flintknapping supplier that I found whilst looking for images of cavalry lances. I didn't look too deeply into their website, but the majority of their products are geared towards stone and bronze age hunting tools.

http://nativeway.safewebshop.com/

Overview

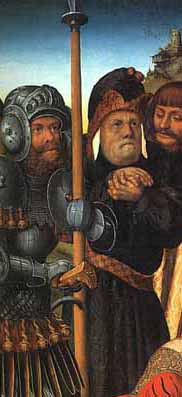

Native way is selling these as "socketed lance heads" fit for a wide range of cultures and time periods. This assessment is fairly accurate; the head is a very generic elongated diamond shape with a diamond cross section, built on a large, heavy duty socket. The measurements provided were 14 inches length overall, 1 3/4 inches wide, though I measured the head at the widest point. The blade itself is 9 inches long. The socket is 5 inches long with an interior diameter of 1 1/8 inches wide. Native Way informed me that they were made in Pakistan but did not specify the manufacturer.

Fit and Finish

The heads are carbon steel and were shipped in plastic bags covered in grease. Once the grease was wiped away, some discoloration on both heads was evident, but polished out fairly easily. Of the two heads I purchased, one had the very last two millimeters of the tip broken off. Normally I would have returned the damaged head, but I wanted one for display and one for hard use anyhow. The overall construction is very stout; the socket is 2mm thick, and the blade exhibits a constant distal taper from 6mm at the socket joint down to less than 1mm at the tip. One gets the immediate impression that this was built for hard use, but retains an elegant simplicity that is very pleasing to the eye. No rivet hole was provided, but the sockets are easy enough to tap that this was not a problem.

Handling Characteristics

Off the haft, the socket seems unnaturally bulky, but one mounted on a short (6ft) haft this makes the head very agile; again the design proves to be well thought out. Thrusts are forceful but easy to recover. There is sufficient edge on the front half of the blade to slash against an unarmored target. This is a very quick and deadly sharp tool.

Conclusion

Native way is currently offering these lance heads for $20 a piece. At this price these are an excellent purchase, and I almost wish I had bought a couple more as gifts.