| Author |

Message |

Sean Flynt

|

Posted: Thu 01 Dec, 2005 11:17 am Post subject: Another DIY Rondel Dagger Posted: Thu 01 Dec, 2005 11:17 am Post subject: Another DIY Rondel Dagger |

|

|

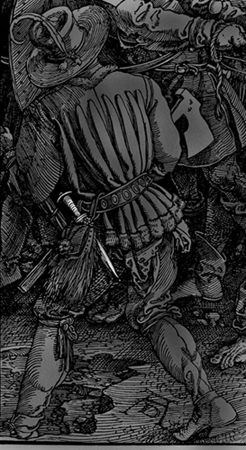

This piece is intended to represent a common German soldier's rondel dagger (Scheibendolch) of ca. 1510. Two examples depicted by Albrecht Dürer in woodcuts dated 1510 served as inspiration (see images below). Mine combines elements of both, but is in some ways speculative because the illustrations don't show details of the orignals' blades. They appear to be relatively broad and of flattened diamond section, though.

Components for my project included an 8" Arkansas Toothpick blade from Atlanta Cutlery (approx. $12), two large washers from Lowes, poplar for the grip, chamois for the grip cover (no cord underwrap-I've found that a temporary cord overwrap during drying gives the neatest effect), and a modified wing nut for the pommel nut. That's it. Less than $20 in parts.

I assembled the piece with JB Weld, slipped on the modified wingnut and cold-peened the tang before the JB Weld set. Of course, it was much more work than that–carving, filing, wrapping, polishing, sanding, etc.

I'm not thrilled with my freehand shaping of the grip (a concave cylindrical taper is much more challenging than a straight taper unless you have a lathe, and I don't have one). The textured grip wrap is speculative and probably not correct, but I think it looks nice and improves the feel of the weapon (the horizontal lines on the grip in the first of the illustrations below don't suggest a wrap. Rather, I think they're just engraving lines to indicate the shape of the object). I switched lower rondels at the last minute and did a sloppy job of filing the replacement, so it doesn't quite sit flush with the blade as planned. The edges of the peen split slightly (another lesson learned), but I'm not unhappy with the result. This is supposed to be a common soldier's weapon, after all. The finished piece feels very comfortable, tight and strong, and the proportions seem about right, judging from the Dürer woodcuts. It looks kind of pitiful compared to Risto's recent creation, but I'm still learning.

Attachment: 98.04 KB Attachment: 98.04 KB

Attachment: 84.11 KB Attachment: 84.11 KB

Attachment: 50.3 KB Attachment: 50.3 KB

Attachment: 100.05 KB Attachment: 100.05 KB

Attachment: 103.98 KB Attachment: 103.98 KB

-Sean

Author of the Little Hammer novel

https://www.amazon.com/Little-Hammer-Sean-Flynt/dp/B08XN7HZ82/ref=sr_1_1?dchild=1&keywords=little+hammer+book&qid=1627482034&sr=8-1

Last edited by Sean Flynt on Thu 01 Dec, 2005 11:33 am; edited 4 times in total

|

|

|

|

|

Russ Ellis

Industry Professional

|

Posted: Thu 01 Dec, 2005 11:27 am Post subject: Re: Another DIY Rondel Posted: Thu 01 Dec, 2005 11:27 am Post subject: Re: Another DIY Rondel |

|

|

Hey Sean... sounds great but is there a picture here somewhere that I'm not seeing?

TRITONWORKS Custom Scabbards

|

|

|

|

Sean Flynt

|

|

|

|

Kirk Lee Spencer

|

Posted: Thu 01 Dec, 2005 12:17 pm Post subject: Posted: Thu 01 Dec, 2005 12:17 pm Post subject: |

|

|

very nice work Sean!

I really like the overall design... It really flows together.

ks

Two swords

Lit in Eden’s flame

One of iron and one of ink

To place within a bloody hand

One of God or one of man

Our souls to one of

Two eternities

|

|

|

|

|

Russ Ellis

Industry Professional

|

Posted: Thu 01 Dec, 2005 12:23 pm Post subject: Posted: Thu 01 Dec, 2005 12:23 pm Post subject: |

|

|

| Sean Flynt wrote: | | Sorry about that, Russ! You caught me just as I was tweaking the photos. They should all show now. I thought about you while making this piece because I was also thinking about whether or not to make a sheath as well. Might still do it. |

Ahh there we go! Nice job there Sean. If you woudn't have fessed up about the components no one would have ever believed it.  I've got my own little project to work on this weekend... I've got my own little project to work on this weekend...

TRITONWORKS Custom Scabbards

|

|

|

|

John Cooksey

|

Posted: Thu 01 Dec, 2005 12:30 pm Post subject: Posted: Thu 01 Dec, 2005 12:30 pm Post subject: |

|

|

Sweet!!!

That is very, very cool.

And, IMO, very much "in the spirit" of making do with whatcha got.

I didn't surrender, but they took my horse and made him surrender.

|

|

|

|

Glen A Cleeton

|

Posted: Thu 01 Dec, 2005 12:31 pm Post subject: Posted: Thu 01 Dec, 2005 12:31 pm Post subject: |

|

|

Looks great. A simple workaround for small lathe work could have been a carraige bolt and nut. Long enough that the threads can chuck in a drill. Small stuff can be done, paper in one hand, drill in the other but you can clamp the drill down.

With enough shop space, a small spring pole lathe could be slapped together pretty quickly.

Cheers

GC

|

|

|

|

Sean Flynt

|

Posted: Thu 01 Dec, 2005 12:46 pm Post subject: Posted: Thu 01 Dec, 2005 12:46 pm Post subject: |

|

|

| Glen A Cleeton wrote: | Looks great. A simple workaround for small lathe work could have been a carraige bolt and nut. Long enough that the threads can chuck in a drill. Small stuff can be done, paper in one hand, drill in the other but you can clamp the drill down.

With enough shop space, a small spring pole lathe could be slapped together pretty quickly.

Cheers

GC |

Thanks for the positive feedback, folks!

Hmmm...I considered setting up a spring pole lathe but decided it would be too much hassle. Although I also considered and dismissed rigging up something relatively complicated with a drill, I didn't occur to me to simply hold the drill and use coarse paper to do the rough shaping. That's a very interesting and simple idea! There's a Roman spatha on my project list, so maybe I'll employ some technology for the grip. Thanks for the tip!

-Sean

Author of the Little Hammer novel

https://www.amazon.com/Little-Hammer-Sean-Flynt/dp/B08XN7HZ82/ref=sr_1_1?dchild=1&keywords=little+hammer+book&qid=1627482034&sr=8-1

Last edited by Sean Flynt on Thu 01 Dec, 2005 12:48 pm; edited 1 time in total

|

|

|

|

Sean Flynt

|

|

|

|

|

Wolfgang Armbruster

|

Posted: Thu 01 Dec, 2005 12:58 pm Post subject: Posted: Thu 01 Dec, 2005 12:58 pm Post subject: |

|

|

This one looks great, the blade seems be quite thick and durable.

The woodcuts are amazing as well. Do you know where I can get the full versions?

The upper one appears to be by Dürer. And I thought I know all his works

|

|

|

|

Sean Flynt

|

|

|

|

Bill Grandy

myArmoury Team

|

Posted: Thu 01 Dec, 2005 1:39 pm Post subject: Posted: Thu 01 Dec, 2005 1:39 pm Post subject: |

|

|

Very nice job, Sean! The hilt work looks very nice. The blade looks a little "fat" compared to most rondel daggers I've seen, but I also understand that you're working with what's available. Have you seen any examples of originals with less acute tips such as with the Atlanta cutlery blade?

HistoricalHandcrafts.com

-Inspired by History, Crafted by Hand

"For practice is better than artfulness. Your exercise can do well without artfulness, but artfulness is not much good without the exercise.” -anonymous 15th century fencing master, MS 3227a

|

|

|

|

Sean Flynt

|

Posted: Thu 01 Dec, 2005 1:59 pm Post subject: Posted: Thu 01 Dec, 2005 1:59 pm Post subject: |

|

|

| Bill Grandy wrote: | | Very nice job, Sean! The hilt work looks very nice. The blade looks a little "fat" compared to most rondel daggers I've seen, but I also understand that you're working with what's available. Have you seen any examples of originals with less acute tips such as with the Atlanta cutlery blade? |

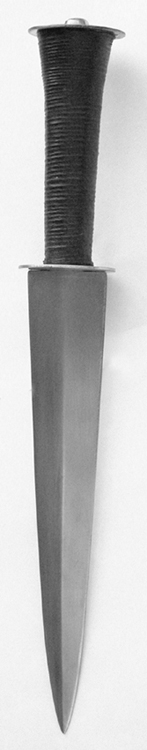

Well spotted! Yep, it's not only broader (and thinner?) than any I've seen, it does also have that convex profile taper, sort of like an Oakeshott Type XVIII sword blade. So, yes, the tip would normally be more acute on straight taper blades (like Oakeshott XV). On the other hand, the width and profile of my blade resemble the classic Swiss (Holbein) daggers of the same period. Those blades often have a ricasso, however (the one shown below does not). I've often thought that these Arkansas Toothpick blades would serve well in a Holbein project based on examples such as this one:

Attachment: 8.27 KB Attachment: 8.27 KB

-Sean

Author of the Little Hammer novel

https://www.amazon.com/Little-Hammer-Sean-Flynt/dp/B08XN7HZ82/ref=sr_1_1?dchild=1&keywords=little+hammer+book&qid=1627482034&sr=8-1

|

|

|

|

|

Joe Fults

|

Posted: Thu 01 Dec, 2005 2:27 pm Post subject: Posted: Thu 01 Dec, 2005 2:27 pm Post subject: |

|

|

Very well done for a McGiver job. :-)

Wonder what it would be like with thicker washers...assuming some could be found.

"The goal shouldn’t be to avoid being evil; it should be to actively do good." - Danah Boyd

|

|

|

|

Sean Flynt

|

Posted: Thu 01 Dec, 2005 2:38 pm Post subject: Posted: Thu 01 Dec, 2005 2:38 pm Post subject: |

|

|

| Joe Fults wrote: | Very well done for a McGiver job. :-)

Wonder what it would be like with thicker washers...assuming some could be found. |

Funny you should wonder...I wondered the same thing as I researched and thought about how to do this. Thin, washer-like rondels are historically plausible, but most rondels seem to be slightly thicker and some are quite thick. The second illustration above shows a thick pommel rondel. I didn't find any off-the-shelf washers thick enough to approximate such a rondel but it seems that some rondel daggers featured gaurds and pommels of sandwich construction (thin metal disk, wooden disk, thin metal disk). That would be the easiest way to create thicker rondels with off-the-shelf parts, and it would be historically appropriate, it seems. Perhaps some rondel experts will chime in here and offer details about those weapons. I didn't pursue the design because I don't find it particularly attractive.

-Sean

Author of the Little Hammer novel

https://www.amazon.com/Little-Hammer-Sean-Flynt/dp/B08XN7HZ82/ref=sr_1_1?dchild=1&keywords=little+hammer+book&qid=1627482034&sr=8-1

|

|

|

|

Sean Flynt

|

|

|

|

|

Russ Ellis

Industry Professional

|

Posted: Fri 02 Dec, 2005 5:56 am Post subject: Posted: Fri 02 Dec, 2005 5:56 am Post subject: |

|

|

| Sean Flynt wrote: | | Russ Ellis wrote: | I've got my own little project to work on this weekend...  |

Is it long and pointy? |

Why yes, yes it is...

TRITONWORKS Custom Scabbards

|

|

|

|

Greg Griggs

|

Posted: Fri 02 Dec, 2005 9:02 am Post subject: Posted: Fri 02 Dec, 2005 9:02 am Post subject: |

|

|

Nice job Sean. Like the way you used simple items to make such a neat piece. FYI - they make what is called a "machine" washer that is readily available which is double the thickness of a normal washer, and are still inexpensive.

Not one shred of evidence supports the notion that life is serious.

|

|

|

|

Bill Grandy

myArmoury Team

|

Posted: Fri 02 Dec, 2005 9:42 am Post subject: Posted: Fri 02 Dec, 2005 9:42 am Post subject: |

|

|

Wow, Sean, your pictures make it look so simple! I'm almost tempted to give this a try myself!

HistoricalHandcrafts.com

-Inspired by History, Crafted by Hand

"For practice is better than artfulness. Your exercise can do well without artfulness, but artfulness is not much good without the exercise.” -anonymous 15th century fencing master, MS 3227a

|

|

|

|

Sean Flynt

|

|

|

|

|

|