| Author |

Message |

Folkert van Wijk

|

Posted: Sun 27 Feb, 2005 2:54 pm Post subject: Iron and bronze working questions. Posted: Sun 27 Feb, 2005 2:54 pm Post subject: Iron and bronze working questions. |

|

|

I was wondering about those iron Celtic scabbards, like the one so beautiful recreated by Patrick Bárta, and that's bin reviewed lately here.

How would these two halves be attached to each other in those days??

These scabbards exist of two halves one half has an edge that accommodates the edge of the other half.

But how would they hold on to each other??? Just by the strenght of the iron? Are the edges of these two parts hammered and forged on to each other or did they use a kind of solder technique?

And where these Iron scabbards only made of iron, or was there also a wood construction inside?

And in general: what techniques where there in those days to attache to peases of iron or bronze to eatch other??

you see there are a lot of metallurgic riddles for me...

A good sword will only be sharp, in the hands of a wise man…

I am great fan of everything Celtic BC, including there weapons.

|

|

|

|

Greyson Brown

|

Posted: Mon 28 Feb, 2005 4:45 am Post subject: Posted: Mon 28 Feb, 2005 4:45 am Post subject: |

|

|

Folkert,

I am no expert, but I do have a little knowledge, so I'll try to help you out.

A lot of non-steel tools and components throughout history were made of wrought iron. Wrought has almost no carbon in it and is very easy to work. I have not had the privilege of using it myself, but have testomony from several reliable individuals that they could consistantly make forge welds with wrought iron that they would never have even tried with mild steel. So it would have been possible to weld two pieces together. The biggest single trick (which actually involves multiple parts) when forge welding is to get the metal as hot as possible without burning the carbon in it (which is where the low carbon content of wrought iron comes in handy), and then hit it before it gets cold. With something like two halves of a scabbard, there really is not much mass and it would be veryeasy to lose heat before you could hit it. That would not be a huge problem, as you can pretty much keep trying until you pound out your metal into tin foil, but it would be really really frustrating!

It is also possible that pieces would have been brazed together. To be honest, I don't know much about brazing, and have never done it myself, but it is relatively similar to soldering. Essentially, brazing consists of melting a softer (i.e. has a lower melting point), non-ferrous metal and using it to hold to other pieces of metal together. I think the biggest difference between soldering and brazing is the bit about the filler being non-ferrous, but I'm not really sure. If you were to mess up while brazing, you should (at least theoretically) be able to melt out the filler (because it will melt before the other pieces) and start over without any damage to the rest of the scabbard, or whatever other project you are working on. You indcated that one half of the scabbard has an edge that accomodates the other. If this were some kind of tongue-in-groove construction, or something similar, it might provide a channel for the brazing filler to flow into. That would probably help to ensure that everything got held together consistantly along the length of the scabbard.

Thus, especially given the edges of the scabbard halves, I think it is most likely that the scabbards you were asking about would have been brazed together. That said, the only historical techniques that I am aware of for holding two pieces of iron or bronze together are welding, brazing, and more obvious things like rivets. There might be something out there that I have not considered. Hope that helps at least a little bit.

-Grey

"So long as I can keep the path of honor I am well content."

-Sir Arthur Conan Doyle, The White Company

|

|

|

|

|

Nathan Bell

|

Posted: Mon 28 Feb, 2005 9:28 am Post subject: Posted: Mon 28 Feb, 2005 9:28 am Post subject: |

|

|

Hi Folkert,

These scabbards were crimped at the edges. It's a process which seems a bit modern, often how metal gutter sections are fastened togethr. My Barta scabbard is made the same way.

Basically either the front plate has a few millimeters extra width than the back(usually in celtic swords) or the back is a bit wider than the front (more rare but still seen on some scabbards)....the thin extra bit is then folded over the other plate and a pressure is exerted along a thin, fine line basically making a "fold" at the edges.

The very bottom portion of the scabbrd does not have the crimped metal, but is rather held by the chape. The chape is sort of like a very narrow gutter shaped clamp that runs along both sides and the point section of the scabbard. These chapes are very distinctive and "sensitive" by time period....the form of the chape is often the best identifier of the age and period of the celtic sword.

Typically, the scabbards are very thin and fit very closely to the blade. There have been isolated finds with a thn bit of leather lining or thin slats of wood. Here we are talking about a very thin scabbard lining of wood or leather, with still a very tight fit to the blade.

On the Continent, the scabbards were typically of iron, and bronze was the exception. In Britain, the opposite was generally true.

Hope this helps,

Nate

|

|

|

|

Greyson Brown

|

Posted: Tue 01 Mar, 2005 3:14 am Post subject: Posted: Tue 01 Mar, 2005 3:14 am Post subject: |

|

|

Well, that makes sense. Why didn't I think of that one? At least now we know.

-Grey

"So long as I can keep the path of honor I am well content."

-Sir Arthur Conan Doyle, The White Company

|

|

|

|

|

Jonathon Janusz

|

Posted: Tue 01 Mar, 2005 5:01 am Post subject: Posted: Tue 01 Mar, 2005 5:01 am Post subject: |

|

|

Nathan,

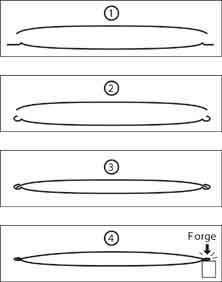

Forgive me for being spatially inept, but could I trouble you (or someone else?) for a quick sketch of the crimping - I just can't get my head around the description.

Thanks!

|

|

|

|

Folkert van Wijk

|

Posted: Tue 01 Mar, 2005 5:20 am Post subject: Drawing Posted: Tue 01 Mar, 2005 5:20 am Post subject: Drawing |

|

|

I quess / think he means something like this....

Attachment: 5.48 KB Attachment: 5.48 KB

A good sword will only be sharp, in the hands of a wise man…

I am great fan of everything Celtic BC, including there weapons.

|

|

|

|

|

Nathan Bell

|

Posted: Tue 01 Mar, 2005 6:08 am Post subject: Re: Drawing Posted: Tue 01 Mar, 2005 6:08 am Post subject: Re: Drawing |

|

|

| Folkert van Wijk wrote: | | I quess / think he means something like this.... |

Yes, Folkert has it!

Folkert illustrates the "back over front" crimping, which was used, but is less typical. The more common was "front over back" crimping where the front plate is the larger one...

Great Illustration Folkert!

N

|

|

|

|

Folkert van Wijk

|

Posted: Tue 01 Mar, 2005 6:13 am Post subject: A nother Posted: Tue 01 Mar, 2005 6:13 am Post subject: A nother |

|

|

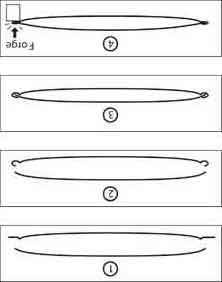

And then the most common way..

(making an illu, is one way of spending your lunch brake...)

Attachment: 5.64 KB Attachment: 5.64 KB

A good sword will only be sharp, in the hands of a wise man…

I am great fan of everything Celtic BC, including there weapons.

|

|

|

|

Greyson Brown

|

Posted: Thu 03 Mar, 2005 4:08 am Post subject: Posted: Thu 03 Mar, 2005 4:08 am Post subject: |

|

|

You know, Folkert, I just would have said that the front of the scabbard was down in the first set of illustrations. Your way is a bit more entertaining though.

-Grey

"So long as I can keep the path of honor I am well content."

-Sir Arthur Conan Doyle, The White Company

|

|

|

|

|

Jonathon Janusz

|

Posted: Thu 03 Mar, 2005 4:44 am Post subject: Posted: Thu 03 Mar, 2005 4:44 am Post subject: |

|

|

Folkert,

Thanks for the illustrations!

I knew things in period were done the way that made sense to the rest of us, just upside down and backwards!

Seriously, though, anyone know of similar scabbard making techniques later in period? Disregarding post-1500 era, Were metal/metal covered scabbards used throughout or in fashion in other periods? Any particulars on manufacture/construction?

Thanks again!

|

|

|

|

Greyson Brown

|

Posted: Sat 05 Mar, 2005 1:56 am Post subject: Posted: Sat 05 Mar, 2005 1:56 am Post subject: |

|

|

| Jonathon Janusz wrote: | | Seriously, though, anyone know of similar scabbard making techniques later in period? Disregarding post-1500 era, Were metal/metal covered scabbards used throughout or in fashion in other periods? Any particulars on manufacture/construction |

I will not claim to be an expert on scabbards, but I think you can say pretty definatively that scabbards from about the fall of Rome through the late medieval period were wood and leather. In the 14th century at least, metal fittings for suspention were common, and in fact the norm, but I am not aware of any evidence for all metal scabbards during that time.

-Grey

"So long as I can keep the path of honor I am well content."

-Sir Arthur Conan Doyle, The White Company

|

|

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

All contents © Copyright 2003-2026 myArmoury.com — All rights reserved

Discussion forums powered by phpBB © The phpBB Group

Switch to the Basic Low-bandwidth Version of the forum

|