| Author |

Message |

Lancelot Chan

Industry Professional

|

Posted: Thu 02 Jun, 2005 4:11 am Post subject: Posted: Thu 02 Jun, 2005 4:11 am Post subject: |

|

|

What I'm practicing is unarmored fighting so a dueling sword would do. In the sparring, a RSW model right after my own sword proved to be very effective fighting sword for me. Now it doesn't have those edge retention problem of course.

Besides edge hardness, upon talking to a friend today whose interests are in antique swords and knives, he wondered about edge toughness. He talked about a famous test presented by a smith whose name escaped from my memory about flexing a knife's edge on a brass rod and then the edge should be able to return true.

I think it may only be feasible on a thin knife edge but maybe other than HRC reading, we can take a look into the edge toughness in swords as well.

| Kenneth Enroth wrote: | | Lancelot Chan wrote: | This could be slightly straying off topic but maybe not if we are talking about edge retention.

Peter Johnsson mentioned that my sword was honed to super sharp level based on my idea 3 years ago in private email exchange. Albion has agreed to ship me a new replacement so this time I want the sword to have an original sharpness on the antique. |

I'd guess that your sword has a standard edge. That "super sharp" theory is just speculation.

As it has been suggested multiple times that the brescia doesn't really fit your needs have you tought about choosing another model as your replacement? |

Ancient Combat Association —http://www.acahk.org

Realistic Sparring Weapons — http://www.rsw.com.hk

Nightstalkers — http://www.nightstalkers.com.hk

|

|

|

|

Kenneth Enroth

|

Posted: Thu 02 Jun, 2005 4:19 am Post subject: Posted: Thu 02 Jun, 2005 4:19 am Post subject: |

|

|

|

Will you do the same tests again on your replacement sword?

|

|

|

|

Lancelot Chan

Industry Professional

|

Posted: Thu 02 Jun, 2005 4:27 am Post subject: Posted: Thu 02 Jun, 2005 4:27 am Post subject: |

|

|

Today I went to my friend Parke's house to do a hardness test on his Squireline 13th Century Warsword. The result was more consistent hardness along the blade length than my spadona, spotting the same number all along the length actually, and lower hardness right behind 0.25 inch of the edge line. I'll leave the full review for him to disclose, though.

Through this, I learned that my sword is indeed a special case.

I will do the same test on my replacement sword, without cutting the leather wrapped pork arm. After all, they were not "test" but my usual practice actually. I have swords that gone through them again and again without need for maintenance and that was how I honed my skill. I understand I will have to maintain the replacement sword more than my other sword, for this is the historical accuracy. I won't complain for it. I'll just report the result as plain as it is if anybody is interested. ( I guess many of you are tired of me already )

Ancient Combat Association —http://www.acahk.org

Realistic Sparring Weapons — http://www.rsw.com.hk

Nightstalkers — http://www.nightstalkers.com.hk

|

|

|

|

Kenneth Enroth

|

Posted: Thu 02 Jun, 2005 4:34 am Post subject: Posted: Thu 02 Jun, 2005 4:34 am Post subject: |

|

|

| Lancelot Chan wrote: | | ( I guess many of you are tired of me already ) |

No, as this story has developed it has become very educational and valuable for a lot of potential sword buyers.

|

|

|

|

|

Jesse Frank

Industry Professional

Location: Tallahassee, Fl Joined: 04 May 2005

Posts: 144

|

Posted: Thu 02 Jun, 2005 5:03 am Post subject: Posted: Thu 02 Jun, 2005 5:03 am Post subject: |

|

|

| Quote: | | What I'm trying to say here, is that its alright to have a lot of pearlite in a larger sword, or a sword with a wide, thick forte. But a light slender sword that might be used heavily, had better have a body of tempered martensite, or with the custom guys, maybe lower bainite....... A lot of pearlite in a lighter sword would likely leave the blade vulnerable to taking a set in a pooched cut....... |

Doh!

I should have clarified

I agree completely. What I should have said was that I would prefer a body of tempered martensite, with the forte being drawn back a bit more.

This has been a great thread!

|

|

|

|

|

Angus Trim

|

Posted: Thu 02 Jun, 2005 8:43 am Post subject: Posted: Thu 02 Jun, 2005 8:43 am Post subject: |

|

|

| Peter Johnsson wrote: |

Hey,

Good post Gus!

This shows very well the different aspects you have to weigh against each other in the developing of swords and manufactuirng techniques. There are many roads to follow and all have their possibilities and limitations. Most can lead to good results. It all about how you follow the road of I am allowed to grow Philosophcal

I also agree with you that tempered martensite is a good thing. I like it too. I would not make to big a deffierence between us here.

What I mentioned about structure with a mixture of pearlite, bainite and martensite is what I´ve read about originals.

Since the 1075 is not too different from historical steel it will react more on varying cooling rates than a more high alloy steel. If you sometimes in some blades don´t get martensite all the way around the surface of the sword (the core at the ticker parts will always show som mix of other structures) you will observe that the base of the sword is the part ehre there mght be some other sturctures showing. The edge will (or should I say should) have martensitic structure and also the ain parts of the sword where flexing and cutting happens. What I wnated to get across is that some softer structures at the base of the sword, wawy from the edge might not be detrimental, and in the case of carbon steel might even be beneficial.

Not in every case, and especially not in the type of blades you mention: slim lightweight blades for heavy duty. Those need all the tempered martensite they can get.

We are very much in agreement here Gus.

...Can you imagine!?!?    |

Hi Peter

Over the last seven years, we've had many, many more points of agreement than disagreement. And for the most part, the disagreements have been over details, except for a couple of celebrated incidents.......and then, really, a couple of well chosen words at the right time likely would have prevented the explosions.

Badly chosen words, passionate people, a passionate subject...... not a good mix.....

Sometimes today, things like discussing heat treat, edge geometry, things of this nature, if its approached right, words chosen carefully, then different viewpoints can be expressed without flames. Then, wonder of wonders, more agreement is ussually seen than disagreement.......

Sometimes things need clarification, things like this conversation, where once things are taken into context, it can be seen that different structures in the steel, each would be ok given different kinds of structures. Differing kinds of swords, differing kinds of dynamics, differing requirements in the structures......

Clarification is sometimes a good thing.........

swords are fun

|

|

|

|

|

Joe Leung

Location: Hong Kong Joined: 02 Jun 2005

Posts: 8

|

Posted: Thu 02 Jun, 2005 9:22 am Post subject: Posted: Thu 02 Jun, 2005 9:22 am Post subject: |

|

|

| Peter Johnsson wrote: | | Lancelot Chan wrote: | | Thanks PJ for your info. I've shot Mike an email to see if I can get a replacement with more consistent blade hardness along the length and original sharpness or not. We'll see how it turns out. |

Hey Lance!

You can choose to make swords from a number of different steels within certain limits. Whatever you choose it will infliuence most every work procedure the blade goes through: shaping (forging or stock removal), heat trating, finish grinding and sharpening. You cannot pick one aspect, like hardness, and say it is the most important one. Grainsize is equally important for edge retention and resiliency. You cannot test for grain size with a hardness test.

Hardness is just one af many equally important aspects in a sword blade. Grain size, alloy content, edge type, blade type, distribution of mass, dynamic aspects, cross section...I could go on. A thing like hardness must be blanced against all other factors in a blade. Blade shape, cross section, intended function and steel used are perhaps the most important ones.

Best

Peter |

It is really a very informative thread. But there is one question that I would like to raise. How can a swordsmith/company ensure that there is enough/adequate edge toughness for their products?

I've read that multple quench and tempering can vastly improve and refine the grain structure. And testing the edge toughness maybe as easy as try to flex the edge with a brass rod and let it return to true.....or break the blade and observe under microscope...... or maybe send the sample to a metallurgical laboratory. Will any company at least do some of these to their swords, at least initially when they start certain treat treating protocol?

Joe

|

|

|

|

|

Joe Leung

Location: Hong Kong Joined: 02 Jun 2005

Posts: 8

|

Posted: Thu 02 Jun, 2005 9:54 am Post subject: Posted: Thu 02 Jun, 2005 9:54 am Post subject: |

|

|

| Thomas Jason wrote: | FYI Lance:

The Japanese cutting of dead bodies was considered a form of destructive testing. The cuts were made until wither the blade failed to go the whole way through or the edge sustained a certain level of damage, at which point the cuts were generally ended. Swords that survived were then repolished and returned to the customer.

GEnerally only a single sword that was representative of the maker's work was used in the testing. And even then swords from highly prized makers were not subjected to the tests. |

This kind of tests is not destructive......at least not intentionally. I do agree that some of the swords that are not up to standard will be destroyed in the test.

That's why the person who did the cutting is almost always a high ranking samurai with good swordmanship (Some swordsmith do test cuttings in shinshinto times).

This kind of test cutting never use living objects.......all decapitated (executed) before used for test cutting.

This kind of test was intended to show off the work of the swordsmith....like a commercial nowadays.....on the contrary, you will never know whether the test cutting personel will get any benefits from famous swordsmith.

But there are plenty of sword with test cutting inscriptions on the tang which is in wonderful condition.

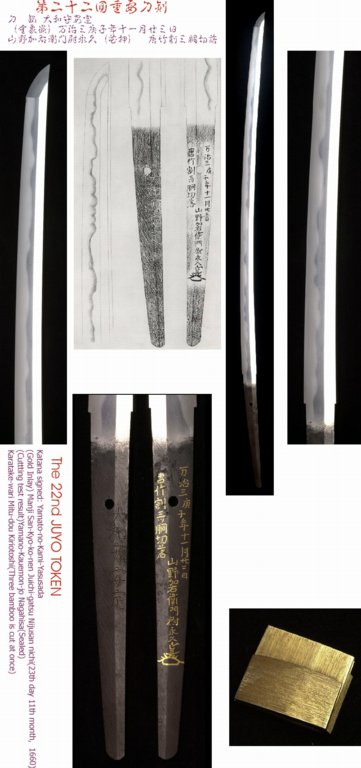

Attachment: 48.44 KB Attachment: 48.44 KB

This is a sword with test cutting inscription. Is it in bad shape?

|

|

|

|

Nathan Robinson

myArmoury Admin

|

|

|

|

Jean Thibodeau

|

Posted: Thu 02 Jun, 2005 10:24 am Post subject: Posted: Thu 02 Jun, 2005 10:24 am Post subject: |

|

|

O.K. the test cut wasn't the THE killing stroke, but the body was still warm ( Gulp ) and bones had no time to dry out and harden.

If I remember a story I read the condemmed man said, something to the effect, that if he had known that the cut was going to be across the abdominal cavity: He would have swallowed a stone to ruin the sword.

The story didn't mention that he would be decapitated first. He may well have been decapitated first and these stories could be the ancient Japanese equivalent of an urban legend. ( Not an area where I can claim expertize. )

Also, in either case he probably died much faster than the usual execution method which I think involved a slow death by a form of cruxifiction. ( Depending on the historical period maybe. )

You can easily give up your freedom. You have to fight hard to get it back!

|

|

|

|

|

Joe Leung

Location: Hong Kong Joined: 02 Jun 2005

Posts: 8

|

Posted: Thu 02 Jun, 2005 10:32 am Post subject: Posted: Thu 02 Jun, 2005 10:32 am Post subject: |

|

|

| Nathan Robinson wrote: | | Joe Leung wrote: | | But there are plenty of sword with test cutting inscriptions on the tang which is in wonderful condition. |

Of course. But the real question is if it's reasonable to expect that these swords received a polish or any other repairs after the cutting tests. |

Yes of course it is reasonable to expect that these sword will have to be polished after such a test. (I would be reluctant to use the word repair)...but please be reminded that the construction of japanese sword is a that a jacket of high carbon steel covering a core of low carbon steel. So the extend to which the sword needed to be polish is very important.....is any change of shape neccessary?

And remember that the test cutting is like a commercial, an ad in the old days. If the sword sustained so much damage that reshape is necessary, then most probably the sword will be regarded as not passing the test.

Joe

|

|

|

|

|

Joe Leung

Location: Hong Kong Joined: 02 Jun 2005

Posts: 8

|

Posted: Thu 02 Jun, 2005 10:41 am Post subject: Posted: Thu 02 Jun, 2005 10:41 am Post subject: |

|

|

| Jean Thibodeau wrote: | O.K. the test cut wasn't the THE killing stroke, but the body was still warm ( Gulp ) and bones had no time to dry out and harden.

If I remember a story I read the condemmed man said, something to the effect, that if he had known that the cut was going to be across the abdominal cavity: He would have swallowed a stone to ruin the sword.

The story didn't mention that he would be decapitated first. He may well have been decapitated first and these stories could be the ancient Japanese equivalent of an urban legend. ( Not an area where I can claim expertize. )

Also, in either case he probably died much faster than the usual execution method which I think involved a slow death by a form of cruxifiction. ( Depending on the historical period maybe. ) |

Hello Jean,

Test cutting in old Japan is an serious act. And testing on criminals are to be avoided. Sword testing is not execution and cannot be considered to be equivalent. Swords are valuable things in old Japan...not monetarily but almost spiritually. That's why swords can be preserved so nicely throughout the centuries. Western antique swords has to be found in river bed, under soil at least. But antique Japanese swords are found in ordinary Japanese families....taken well care of through different generations.

Joe

Last edited by Joe Leung on Thu 02 Jun, 2005 10:43 am; edited 1 time in total

|

|

|

|

Nathan Robinson

myArmoury Admin

|

Posted: Thu 02 Jun, 2005 10:42 am Post subject: Posted: Thu 02 Jun, 2005 10:42 am Post subject: |

|

|

| Joe Leung wrote: | Yes of course it is reasonable to expect that these sword will have to be polished after such a test. (I would be reluctant to use the word repair)...but please be reminded that the construction of japanese sword is a that a jacket of high carbon steel covering a core of low carbon steel. So the extend to which the sword needed to be polish is very important.....is any change of shape neccessary?

And remember that the test cutting is like a commercial, an ad in the old days. If the sword sustained so much damage that reshape is necessary, then most probably the sword will be regarded as not passing the test. |

I'm just trying to make sure we always keep this in context. There is always a big risk in not explaing these issues fully. The 'net community has long since held onto the idea of the "indestructible sword" that can cut through multiple things without showing any signs of use. This is an unrealistic expectation, but we have to remember that many readers have this in their minds as they read our conversations.

This is interesting stuff. Please refer me to your references so I can read more about these tests and the expected results from them.

.:. Visit my Collection Gallery :: View my Reading List :: View my Wish List :: See Pages I Like :: Find me on Facebook .:.

|

|

|

|

Gabriel Stevens

|

|

|

|

|

Joe Leung

Location: Hong Kong Joined: 02 Jun 2005

Posts: 8

|

Posted: Thu 02 Jun, 2005 10:54 am Post subject: Posted: Thu 02 Jun, 2005 10:54 am Post subject: |

|

|

| Nathan Robinson wrote: | | Joe Leung wrote: | Yes of course it is reasonable to expect that these sword will have to be polished after such a test. (I would be reluctant to use the word repair)...but please be reminded that the construction of japanese sword is a that a jacket of high carbon steel covering a core of low carbon steel. So the extend to which the sword needed to be polish is very important.....is any change of shape neccessary?

And remember that the test cutting is like a commercial, an ad in the old days. If the sword sustained so much damage that reshape is necessary, then most probably the sword will be regarded as not passing the test. |

I'm just trying to make sure we always keep this in context. There is always a big risk in not explaing these issues fully. The 'net community has long since held onto the idea of the "indestructible sword" that can cut through multiple things without showing any signs of use. This is an unrealistic expectation, but we have to remember that many readers have this in their minds as they read our conversations.

This is interesting stuff. Please refer me to your references so I can read more about these tests and the expected results from them. |

首斬り浅右衛門刀剣押形

The book is in a friend's collection...written in showa 45 (1971) showing the drawing of the sword tested by 浅右衛門 in 18th century.

There are books of test cutting written by the samurai 浅右衛門 in 18th century (reprinted early after WWII) but I was unable to find one.

Joe

|

|

|

|

Jean Thibodeau

|

Posted: Thu 02 Jun, 2005 11:20 am Post subject: Posted: Thu 02 Jun, 2005 11:20 am Post subject: |

|

|

Found my reference to the use of criminals condemned to death:

" It was tested on a human corpse that might be suspended in various positions to permit different cutting strokes.

Sometimes a criminal condemned to death. One story tell of a burly robber who sat in the stocks awaiting execution. When the swordsman walked up with a naked blade he asked: " Is it you who will cut me down ?"

" Yes was the reply ........ " I shall cut you in KESA ( Shoulder to side ) style ...... "

" If I had known it before, " said the robber, " I would have swallowed a couple of big stones to spoil your sword."

Source: Great ages of man, a history of the world's cultures, EARLY JAPAN, by Jonathan Norton Leonard, and the Editors of

TIME-LIFE BOOKS, 1968. Page 79.

Now this one source could be wrong, but this is where I got my information: There is no mention of the idea that precious swords were too sacred to soil on the body of criminals at least as far as this source leaves me to believe.

I'm quite ready to accept the opposite if better quality sources contradict my source.

You can easily give up your freedom. You have to fight hard to get it back!

|

|

|

|

|

Shane Allee

Industry Professional

Location: South Bend, IN Joined: 29 Aug 2003

Posts: 506

|

Posted: Thu 02 Jun, 2005 12:51 pm Post subject: Posted: Thu 02 Jun, 2005 12:51 pm Post subject: |

|

|

Thanks Thomas, that has pretty much been my understanding as well.

Without getting overly graphic or gory, there is still two different levels of "freshness" being discussed here. The japanese didn't exactly have refrigeration units back then to be keeping bodies for test cutting. While it is dead and the bones have been hardening, it hasn't had as long to as a piece of pork from the market.

If a person really wanted to get a better feel and cut meat, something like a soft wood dowel or something similar inserted into the meat would be much better representation.

Shane

|

|

|

|

Eric Meulemans

Industry Professional

|

Posted: Thu 02 Jun, 2005 1:13 pm Post subject: Posted: Thu 02 Jun, 2005 1:13 pm Post subject: |

|

|

| Joe Leung wrote: |

Yes of course it is reasonable to expect that these sword will have to be polished after such a test. (I would be reluctant to use the word repair)...but please be reminded that the construction of japanese sword is a that a jacket of high carbon steel covering a core of low carbon steel. So the extend to which the sword needed to be polish is very important.....is any change of shape neccessary?

Joe |

Regardless of the type of steel or construction method, polishing is, in effect, "repair". When a blade is ground, polished, or otherwise treated to remove nicks, mars, or deformations it necessarily involves the removal of material from the blade. This in turn invariably changes the shape of the blade, however small that change may be.

It is my understanding that the polishing of Japanese blades is an exceedingly labourious and expensive task requiring great skill, and that the removal of say, a small nick or scratch involves work over the entire length of the blade so as to minimize the overall effect such a defect (as well as the subsequent removal of material) might have upon blade shape. Nevertheless, this can only be done so many times, and each time it of course alters, if only slightly, blade geometry.

Steel is steel, and like any material it has its limitations. Whether through use, abuse, or even maintenance, it will be subject to those limitations. Anyone who has carried an heirloom pocketknife can attest that the shape of its blade has changed greatly from the time their father or grandfather first took hold of it...

-Eric

|

|

|

|

|

George Hill

Location: Atlanta Ga Joined: 16 May 2005

Posts: 614

|

Posted: Thu 02 Jun, 2005 2:33 pm Post subject: Posted: Thu 02 Jun, 2005 2:33 pm Post subject: |

|

|

| Nathan Robinson wrote: | | George Hill wrote: | | Just how much harder is a dead bone? Does this vary much by speicies? Should I start a new thread on this subject? |

The details of the subject are a bit off-topic and out of scope for us here, in my humble opinion. |

I started one on Sword fourm if anyone is interisted. It's here.

http://forums.swordforum.com/showthread.php?s=&threadid=52386

Frankly, I see why I was asked to take it elsewhere. Lots and lots of stuff about politics and philosophy, and I see just why our good mods didn't want it here. Its.... Yikes... The details are there if you want them, I won't clutter this post with them.

But there is some interisting information.

To abandon your shield is the basest of crimes. - --Tacitus on Germania

|

|

|

|

|

Matthew Kelty

|

Posted: Thu 02 Jun, 2005 5:32 pm Post subject: My bad... :) Posted: Thu 02 Jun, 2005 5:32 pm Post subject: My bad... :) |

|

|

I accidentally got my threads crossed, so this was posted in the "Quality Control" thread, when I guess it is more in line with the thread here, or both, I dunno, Moderators, do with it what you will, or leave it be...

At any rate:

As far as what a quality blade *should* be able to do or not do, and the potential of the medium of Steel, I just wanted to share with everyone the requirements for the Journeyman status in the American Bladesmith Society, as it serves as a benchmark by which expert knifemakers judge their peers. The only difference between the "Journeyman" and "Master" status, is that the Master's test requires the same feats of a Pattern welded blade.

Excerpted from http://www.americanbladesmith.com/ABS_JSTest.htm

Below are the requirements of the piece itself, and note that *NO* stropping or honing is allowed between the test phases:

The applicant must have personally forged and performed all work on the test blade, with no other person physically assisting in its construction or heat-treating.

Only forged blades may be tested. Applicants for Journeyman Smith must test with a carbon steel knife. Damascus or laminated blades are not allowed as test blades for those seeking Journeyman Smith status.

Once the test begins, no work, not even light stropping, may be done to the test blade.

TEST KNIFE SPECIFICATIONS:

- Overall Length of Knife: Maximum fifteen (15) inches.

- Blade Width: Maximum two (2) inches.

- Blade Length: Maximum ten (10) inches from point to the beginning of either the guard, bolster, or handle of the - blade.

- Handle Configuration: Any handle configuration is acceptable with or without guard, bolsters, ferrule, etc.

- Handle material is irrelevant and solely the choice of the applicant.

- Blade Material: The Journeyman Smith may test with any forged steel of his or her choice except Damascus.

The test must be conducted in the following sequence:

NOTE: ALL TESTS MUST BE PERFORMED BY THE APPLICANT, EXCEPT AS SPECIFICALLY PROVIDED FOR IN THE ROPE CUTTING. THE MASTER SMITH IS TO SUPERVISE AND SERVE AS THE OFFICIAL ABS WITNESS.

1. ROPE CUTTING: THE PURPOSE OF THIS TEST IS TO TEST THE EDGE GEOMETRY AND SHARPNESS.

Applicant is responsible for supplying the test rope and ensuring that it is a minimum of one (1) inch in diameter. If the applicant brings a larger rope, the applicant will be judged using the same criteria as though the rope was one-inch (1) in diameter. The rope is to be hung in a safe manner, so that the end of the rope to be cut hangs loose without touching the floor or any other object. As a safety precaution, the rope is not to be hand held by another person during the rope-cutting test. The hanging end of the rope is to be marked with tape or a marker to clearly indicate the area that is to be cut. The cut must be approximately six (6) inches from the end of the free hanging rope. A minimum of one (1) cut must be made. The applicant is to aim at the mark with a two (2) inch margin of high or low being acceptable. The applicant must sever the rope in two with one stroke. If the applicant fails on the first attempt, the Master Smith will allow two more attempts. However, if the Master Smith believes that the failure to sever the rope is due to the lack of skill or strength of the applicant, the Master Smith may attempt the rope cutting with the test knife. This is a test of the applicant’s ability to make a knife, not to cut with it. If neither the applicant nor the Master Smith successfully cuts the rope, the applicant fails.

2. WOOD CHOPPING: THE PURPOSE OF THIS TEST IS TO DEMONSTRATE EDGE TOUGHNESS.

The chopping test is to be conducted with 2x4 construction grade wood stud. The 2x4 may be either hand held or clamped into a vise or other safe devise. A chopping motion (no whittling) is to be used. The 2x4 must be chopped completely through a minimum of two (2) times. The applicant may choose the area of the 2x4 through which to chop. Following the chopping test, the Master Smith will inspect the edge to determine if there is any noticeable damage to the blade. Any nicks, chips, flat spots, rolled edges, or other deformations of the blade will result in failing the test.

3. SHAVING HAIR: THE PURPOSE OF THIS TEST IS TO DEMONSTRATE EDGE RETENTION.

After the Master Smith approves the quality of the edge, the blade will be returned to the applicant. The applicant must then shave hair using the section of the blade that was most frequently used in the cutting and chopping portions of the test. Enough hair must be shaved to demonstrate that the edge remains keen and shaving sharp.

4. BENDING: THE PURPOSE OF THIS TEST IS TO SHOW THAT THE APPLICANT IS ABLE TO HEAT TREAT A KNIFE WITH A SOFT BACK AND A HARD EDGE.

The bending of the blade is the final test. Safety gear should be worn. At the discretion of the applicant or the Master Smith, the edge may be dulled prior to bending. The Master Smith will mark a line across the width of the blade approximately 1/3 distance from the tip of the blade. The blade will then be inserted into a vise, tip first, such that the blade is placed into the vise up to the mark on the blade. If the vise jaws are rough, smooth metal inserts shall be located on each side of the clamped portion of the blade to protect the blade, when bending the test knife. The blade shall be bent by force applied to the handle. A leverage device, such as a pipe may be used as long as it does not pose a safety risk. The use of such a device is at the sole risk of the applicant and at the discretion of the supervising Master Smith. The applicant will then bend the blade ninety (90) degrees. The supervising Master Smith will signal the applicant when the ninety (90) degree angle has been reached. The blade is allowed to crack at the edge on bending but not beyond approximately two thirds (2/3rds) the width of the blade. However, if any part of the blade chips or any part of the blade or tang breaks off, the applicant fails. Because of the many variables in the size, geometry, and temper line of the blade, the Master Smith using his/her judgment, shall determine if the extent or location of the fracture line is acceptable. The decision of the Master Smith is final.

So, in order, sever a free hanging 1" rope in one stroke, chop two 2x4's, and shave hair, all without "nicks, chips, flat spots, rolled edges, or other deformations", and no stropping or honing in between. I'd be surprised if the Classic swords we all admire even required a re-polish, merely a simple wipedown and rehoned edge if engaged against "fleshy" targets for posterity testing.

With that in mind, surviving a cut at a pork shoulder to me doesn't sound too unrealistic an expectation. The dead bone comments have been all said, but I think the message was missed on Swordforum, and never made it back here. It's not 'dead' bone that matters, it's 'dry' bone. As long as you have a fairly fresh piece of meat and bone, where reasonable precautions have been made to not let it dry out, it's a fairly valid test, and is probably more forgiving than anything other than a "green" 2x4 ("green" meaning a moisture content higher than 6% or so). But enough of bones...

Certainly a knife has different requirements than a sword, as well as many people aim for how to create "the" piece to get them their status, and may not adhere to the standards once they have achieved it, but the intent is that *every* well made blade should be able to undergo this process and survive (the bending test being to the "extreme").

So, given that we know how a quality blade *should* hold up, we can plug that into the end product, and ask how our family of makers test for that result. I think everyone here (Gus, Tinker, et. al) has done a fair job of describing their process, and as we all attest to, these guys *do* deliver quality goods. Do they neccesarily test at the level of scrutiny described above? No, but I think they handle a certain amount of it, and could probably pass 75% of their products through without breaking a sweat, as well as there is a large audience of happy customers backing them up.

Should some new guy roll into town, think back to the ABS requirements, and be sure to ask the maker how he tests his finished products, and see if the objectives of a quality blade are looked at and adhered to, and how well it may stack up against the ABS guidelines.

Angus, Tinker, Craig, Peter, I'm saving my pennies, and in case there are any other Jim 'Atar' Hrisoulas collectors out there, while I've not tested it, his goal is 52C along the edges.

Sincerely,

Matthew

|

|

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

All contents © Copyright 2003-2024 myArmoury.com — All rights reserved

Discussion forums powered by phpBB © The phpBB Group

Switch to the Basic Low-bandwidth Version of the forum

|