| myArmoury.com is now completely member-supported. Please contribute to our efforts with a donation. Your donations will go towards updating our site, modernizing it, and keeping it viable long-term.

Last 10 Donors: Anonymous, Daniel Sullivan, Chad Arnow, Jonathan Dean, M. Oroszlany, Sam Arwas, Barry C. Hutchins, Dan Kary, Oskar Gessler, Dave Tonge (View All Donors) |

| Author |

Message |

Alexander Ren

|

Posted: Mon 30 Jan, 2006 7:48 pm Post subject: Hafting an axe and war hammer Posted: Mon 30 Jan, 2006 7:48 pm Post subject: Hafting an axe and war hammer |

|

|

I just recieved an axe and war hammer from Albion's moat page. I need haft them and want to know what type of wood I should use. I did a search but could not find a previous topic about this. If there is one that has already covered this I would appreciate the information.

Thanks... Alex

"The more you sweat in practice, the less you bleed in battle."

Last edited by Alexander Ren on Tue 31 Jan, 2006 11:12 am; edited 1 time in total

|

|

|

|

|

Gary Grzybek

Location: Stillwater N.J. Joined: 25 Aug 2003

Posts: 559

|

Posted: Tue 31 Jan, 2006 5:46 am Post subject: Re: Hafting and axe and war hammer Posted: Tue 31 Jan, 2006 5:46 am Post subject: Re: Hafting and axe and war hammer |

|

|

| Alexander Ren wrote: | I just recieved an axe and war hammer from Albion's moat page. I need haft them and want to know what type of wood I should use. I did a search but could not find a previous topic about this. If there is one that has already covered this I would appreciate the information.

Thanks... Alex |

I just received a war hammer from them too

Because I have no intention of using mine I grabbed a cheap piece of red oak from a local lumberyard. Red oak is strong but splinters easy. I think ash or hickory would be a better choice. Anyway, I did some decorative carving with braided copper and brass buttons to aid in gripping. A little stain and it's almost finished.

Gary Grzybek

ARMA Northern N.J.

www.armastudy.org

|

|

|

|

Jesse Zinn

Location: NC (USA) Joined: 17 Nov 2003

Posts: 91

|

Posted: Tue 31 Jan, 2006 10:26 am Post subject: Re: Hafting and axe and war hammer Posted: Tue 31 Jan, 2006 10:26 am Post subject: Re: Hafting and axe and war hammer |

|

|

| Alexander Ren wrote: | I just recieved an axe and war hammer from Albion's moat page. I need haft them and want to know what type of wood I should use. I did a search but could not find a previous topic about this. If there is one that has already covered this I would appreciate the information.

Thanks... Alex |

Alex,

Greetings. I would recommend going down to your local hardware store (Ace, True Value, etc., as opposed to the larger home improvement centers), and picking up a straight, hickory, replacement handle for a maul or mattock/pick axe. You will also need to pick up a wood rasp and a file. Then just rasp and file down the shaft head to the appropriate diameter for your pieces, and shape the rest of the handle to your preferred final shape. Also, be sure to check out this site on how to actually "hang" your axe,

http://www.fhwa.dot.gov/environment/fspubs/99232823/index.htm

Good luck!

Jess

|

|

|

|

Alexander Hinman

|

Posted: Tue 31 Jan, 2006 10:47 am Post subject: Posted: Tue 31 Jan, 2006 10:47 am Post subject: |

|

|

Alex,

Ash and Hickory (primarily hickory nowadays) are the usual options, but there's also another wood called Hornbeam (commonly called 'ironwood') which works very well. It depends on how much effort you want to put into sculpting the haft, because Hornbeam is rather hard.

Oak tends to not have the grain density necessary.

Oh, forgot to mention: How are you going to attach your axe/hammer? Are you going to wedge them or use the basic 'top bigger than the bottom'?

|

|

|

|

Alexander Ren

|

Posted: Tue 31 Jan, 2006 11:04 am Post subject: Posted: Tue 31 Jan, 2006 11:04 am Post subject: |

|

|

Thanks for the advice. I will try to get it done in the next week or two when my classes allow and also borrow a digital camera to post a few in progress pictures... Alex

"The more you sweat in practice, the less you bleed in battle."

|

|

|

|

Alexander Ren

|

Posted: Tue 31 Jan, 2006 11:09 am Post subject: Posted: Tue 31 Jan, 2006 11:09 am Post subject: |

|

|

| Alexander Hinman wrote: | Alex,

Ash and Hickory (primarily hickory nowadays) are the usual options, but there's also another wood called Hornbeam (commonly called 'ironwood') which works very well. It depends on how much effort you want to put into sculpting the haft, because Hornbeam is rather hard.

Oak tends to not have the grain density necessary.

Oh, forgot to mention: How are you going to attach your axe/hammer? Are you going to wedge them or use the basic 'top bigger than the bottom'? |

I was planning on wedging them until I read the article that Jesse posted that says not to in favor of "top bigger than the bottom" method that you mentioned. The latter is probably what I will do now but since I have never actually hafted an ax before, only read how to do it, it my take a few attempts to get it right... Alex

"The more you sweat in practice, the less you bleed in battle."

|

|

|

|

|

Kevin Toomey

|

Posted: Tue 31 Jan, 2006 9:16 pm Post subject: Posted: Tue 31 Jan, 2006 9:16 pm Post subject: |

|

|

I think if you read carefully what the author( I did look for his name, but missed it) on the FHWA website is telling us is that he is a soaker, or his wood wedges, like mine work loose when itís dry.

Really all you can do is make the tenon the same size as the bottom of the eye. When the eye is larger at the top, you wedge. This usually takes two. (the eye of the double-bit is fairly unique) The author complains of splitting caused by the second wedge. He rips a slot for the first. Well, you just do the same for the second, cut diagonally across the eye. Both wedges should be wide enough to span the full width of the eye. Wood will work for both. Then when it loosens you can add metal to the diagonal with much less risk of further splitting.

Obviously Iím not much of a researcher so I was very pleased to hear Peter J. describe his findings regarding Viking axes with iron wedges in a distant thread. I donít know why I assumed a through the top tomahawk mount, but could never reconcile it with functionality. Your mileage may differ, but to me it is a futile exercise that is only complete when you drive the handle through the bottom of the eye. The tension that holds the head in place is so perilous, always working loose with head sliding down the helve. So, through the top is for throwing only imo, with its high expectation of breakage. Speaking of breaking, using either method, beat to fit is hard on the eye.

On the other hand I donít care if soaking in oil works, I donít know why.

Usually the wedges will come loose when it gets dry. The first one is split by the second and those chunks sometimes fall out soon after you feel the wobble. (add to or make new) I didnít cut the diagonal back then, used narrow wedges, which caused splits at the top but never propagated down into the handle. With the two Viking axes Iíve done I tried to be more sophisticated, just so it looks better, then I mushroom the top just a little.

I donít think grain orientation is so cut and dry either. With growth rings perpendicular to the edge, the shaft is more flexible and spring like, which of course stores and releases energy in a heavy stroke. The tendency of the parallel-to-bit ringed handle is to bow right or left of center line of swing- dangerous for felling, battle axes, etc, handy for hewing, while the perpendicular ring will bow above or below, yet inline with the center depending on the sapwood orientation. There are trade offs either way. I can also accept that for a battleaxe, maximum rigidity may be best, but for felling, chopping, some whip in the haft is appreciated. I realize this is arms and armour, not kevís woodtalk, but armies do have to build things and were intimate with their options. Such may be a non issue for most but Iíd like to learn more about what has been found but I donít know where to look.

good luck with your projects.

|

|

|

|

Alexander Ren

|

Posted: Fri 03 Feb, 2006 2:29 pm Post subject: Posted: Fri 03 Feb, 2006 2:29 pm Post subject: |

|

|

Kevin,

Thanks for the explaination. I actually just got a hold of a hickery shaft for the axe. I still need to find one for the hammer since I am planning on having a shorter shaft on it. The bottom of the edge on the axe needs a little work on a grinder so I will be working on that before I haft it.

I just took a few pictures with a friend's camera and will be getting them up in a few days when I have some time.

Thanks everyone for your help... Alex[/url]

"The more you sweat in practice, the less you bleed in battle."

|

|

|

|

Alexander Hinman

|

Posted: Fri 03 Feb, 2006 4:54 pm Post subject: Posted: Fri 03 Feb, 2006 4:54 pm Post subject: |

|

|

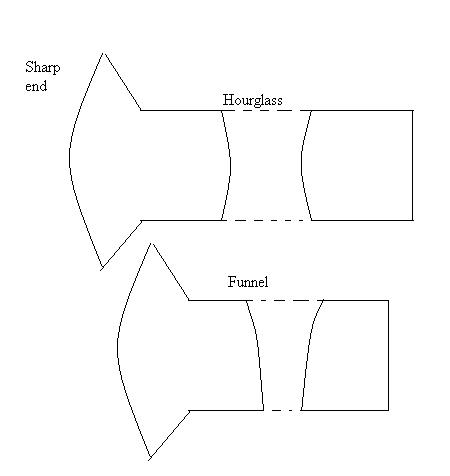

Ah, one thing I should mention. I'm in the process of making an axe after a pattern found in an archaeological excavation. Now, when talking to a much more experienced friend who was helping me make the axe, he discussed the use of a drift, used for shaping the eye. Now, it's important to note that the inside of an axe head can be shaped one of two ways. It could have an hourglass shape, which is always seen on hammers, or a funnel shape, which is the 'tomahawk' kind.

The hourglass is basically a rather gentle incline on the inside of the head, because the drift has gone halfway through the head both ways. This kind of head requires wedging, because the haft's curvature fits into the bottom part of the hourglass, and the wedge spreads out the top.

The funnel shape is basically held by friction.

I heavily advise against hafting a funnel-eye with a wedge, or a hourglass-eye with friction. Your hammer, most likely, is the latter, (since all hammers are made this way) but the axe may well be the former.

Here's a poorly drawn diagram to explain a bit more visually. Mind, the details of the eyes are quite exaggerated.

Attachment: 13.55 KB Attachment: 13.55 KB

|

|

|

|

Alexander Ren

|

Posted: Fri 03 Feb, 2006 10:00 pm Post subject: Posted: Fri 03 Feb, 2006 10:00 pm Post subject: |

|

|

Actually, both eyes are straight as far as I can tell.

"The more you sweat in practice, the less you bleed in battle."

|

|

|

|

|

Kevin Toomey

|

Posted: Sat 04 Feb, 2006 7:03 am Post subject: Posted: Sat 04 Feb, 2006 7:03 am Post subject: |

|

|

| Alexander Hinman wrote: |

I heavily advise against hafting a funnel-eye with a wedge, or a hourglass-eye with friction. Your hammer, most likely, is the latter, (since all hammers are made this way) but the axe may well be the former.

|

Funnel shaped, I like that description. Alexander Hinman, would you mind expanding upon the above, explaining why? I should mention in my description the bottom of the funnel eye rests on a shoulder that prevents the head from slipping down.

|

|

|

|

Alexander Hinman

|

Posted: Sat 04 Feb, 2006 9:31 am Post subject: Posted: Sat 04 Feb, 2006 9:31 am Post subject: |

|

|

Sure thing, Kevin.

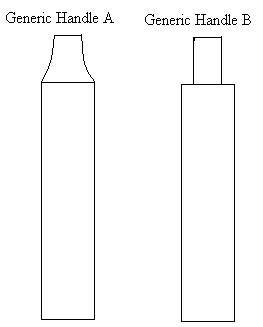

To put it simply, it's either not going to fit or you'd have to do ridiculous amounts of wedging, which wouldn't be very 'stable' if you will. I think another illustration would explain it better. My artistic talents are once again called upon.

Now, the details are once again exaggerated. Anyway, there are two possible handles that you've got for wedging.

The kind I've seen most commonly is type A, but that's on blacksmith hammers, so that's quite possibly not the norm. The problem with type A is that, assuming the lower part of the 'funnel' head fits snugly around the top of the tenon, it won't progress very far at all, making it relatively worthless. If the funnel fits snugly about the bottom part of the tenon, then you've got to use big ol' wedges the cause alot of their own problems. Type A, however, is ideal for the hourglass-shaped eye because the curve fits into the bottom part of the hourglass, and wedging fills the top.

Type B, on the other hand, has the problem of needing a lot of wedging, or relatively big wedges to accomodoate the funnel head, and these pop out more easily because of a lack of tension from the wood that surrounds them, since it's been spread so much.

Now, since the hammer and axe eyes are straight, use wedging, probably with a type B handle.

I don't think you should be too worried about the head sliding down, Kevin, unless you intend to thrust with your axe, which you may very well want to...

What I plan to do with my axe is heat up part of a piece of wire and wrap it around the wood directly under the head. The wire burns into the wood, affixing it in place by making a notch, and when it is fully wrapped, it creates a barrier to keep the axe up. If the handle breaks, just cut the wire with a cold chisel an take the head off.

Attachment: 7.22 KB Attachment: 7.22 KB

|

|

|

|

|

Kevin Toomey

|

Posted: Sat 04 Feb, 2006 7:11 pm Post subject: Posted: Sat 04 Feb, 2006 7:11 pm Post subject: |

|

|

Thanks for taking the time Alexander.

I think you could call the hourglass shape swaged. On some old hammers there is actually a bit of a shoulder where both ends have been widened. In one way the kerf for the wedge allows the handle compress more, to be driven on, then two wedges swell it. Another might only be swaged parallel to the faces, and straight walled front to back, which requires no wedge at all when careully made as the wood recovers from being compressed.

On my Albion Type L the eye is straight. The Hanweii short is a funnel that is 1/8 inch larger at the top. On the L I tapped the lugs closed at the bottom and wider at the top. So you see the wedges are not that large. Hopefully you will get alot of compression from very dry softer wood wedges, which are always trying to swell back. eventually it gets really wet and smahes everything beyond recovery, in the cold by the fire it gets really dry and wedges fall out. If you drop the handle through the top like a pick-axe, then jarring from impacts will work it loose. If you don't tamp it tight every few strokes then like a pick axe the head threatens to loose and slide down the handle.

It was funnel by friction only I was questioning and your caution against doing it.For the above reason. I wondered what I had overlooked, because fitted through the bottom, with a bottom shoulder and wedges I have found to be much better.I feel comfortable with it.

Alex Ren, what axe did you get?

|

|

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

All contents © Copyright 2003-2024 myArmoury.com — All rights reserved

Discussion forums powered by phpBB © The phpBB Group

Switch to the Basic Low-bandwidth Version of the forum

|