| Author |

Message |

|

Scott Kowalski

|

Posted: Fri 05 Jan, 2007 7:34 pm Post subject: Posted: Fri 05 Jan, 2007 7:34 pm Post subject: |

|

|

|

That is looking like an impressive start to what is looking like will be an awesome sword. This is great. Thank you posting this as you go along Matt.

|

|

|

|

|

J. Bedell

|

Posted: Sat 06 Jan, 2007 4:47 am Post subject: Posted: Sat 06 Jan, 2007 4:47 am Post subject: |

|

|

Looking good so far  Thanks for updating us Matt, it's great to see this process! Thanks for updating us Matt, it's great to see this process!

-James

The pen may be mighter, but the sword is much more fun.

|

|

|

|

Matthew Grzybowski

Industry Professional

|

Posted: Sat 06 Jan, 2007 4:55 am Post subject: Posted: Sat 06 Jan, 2007 4:55 am Post subject: |

|

|

| Scott Kowalski wrote: | | That is looking like an impressive start to what is looking like will be an awesome sword. This is great. Thank you posting this as you go along Matt. |

Thanks very much Scott! And to everyone for the kind words.

Now that the steel is here, we'll be able to be updating this thread a little more regular. The hard part of the process is waiting for our outside venders to deliever materials, supplies, or what not. We do what we can to plan so thing keep moving toward the delievery date. Once we receive our materials things generally keep move right along.

Best,

Matt

OlliN Sword Design

Handmade collectible arms, custom swords, and sculpture

www.ollinsworddesign.com

|

|

|

|

|

Terry Crain

|

Posted: Sat 06 Jan, 2007 8:07 am Post subject: OlliN's Custom Shop Project with Jean Thibodeau Posted: Sat 06 Jan, 2007 8:07 am Post subject: OlliN's Custom Shop Project with Jean Thibodeau |

|

|

I find it interesting that this process of creating the sword blade via stock reduction from a thick bar of steel appears so much like the process that sculptor goes through when creating a sculpture. Starting with a block of stone or marble and "releasing" the figure inside.

I never thought of a blade smith as a sculptor, but now must reassess my view in this regard.

I will follow this progress with great interest and appreciate the education in this art.

Terry

Terry Crain

A/K/A

Donal Grant

Honor, not Honors!

|

|

|

|

Jean Thibodeau

|

Posted: Sat 06 Jan, 2007 11:10 am Post subject: Re: OlliN's Custom Shop Project with Jean Thibodeau Posted: Sat 06 Jan, 2007 11:10 am Post subject: Re: OlliN's Custom Shop Project with Jean Thibodeau |

|

|

| Terry Crain wrote: | I find it interesting that this process of creating the sword blade via stock reduction from a thick bar of steel appears so much like the process that sculptor goes through when creating a sculpture. Starting with a block of stone or marble and "releasing" the figure inside.

I never thought of a blade smith as a sculptor, but now must reassess my view in this regard.

I will follow this progress with great interest and appreciate the education in this art.

Terry |

People do still forge blades but most modern production is stock removal either roughed out by CNC machine or in most small operations or single craftsmen shops done handheld totally freehand or partially assisted by some sort of support or guides. Mark does it all handheld and that is " IMPRESSIVE ".

Most custom knife makers also use stock removal by the way and the comparison to sculpture is exactly correct and is why it it up to the maker to figure out all the subtle shapes and transitions that are very difficult to draw.

A shaded drawing in perspective can be close to what the shapes should be but it's easy to cheat when drawing making something difficult seems easy or even draw the geometric incorrectly but looking convincingly correct: When the maker is actually removing material all these little things become decision points where the actual 3D object cannot match the drawing literally but the maker has to make it feel as if it does ! ( Or if the shape isn't possible change the concept to make it possible. ) Since I draw and have done some wood, clay or steel sculpture I have a feel for what I'm trying to explain and hopefully the right words to explain it.

You can easily give up your freedom. You have to fight hard to get it back!

|

|

|

|

|

Mark G.

Industry Professional

|

Posted: Sat 06 Jan, 2007 12:47 pm Post subject: Posted: Sat 06 Jan, 2007 12:47 pm Post subject: |

|

|

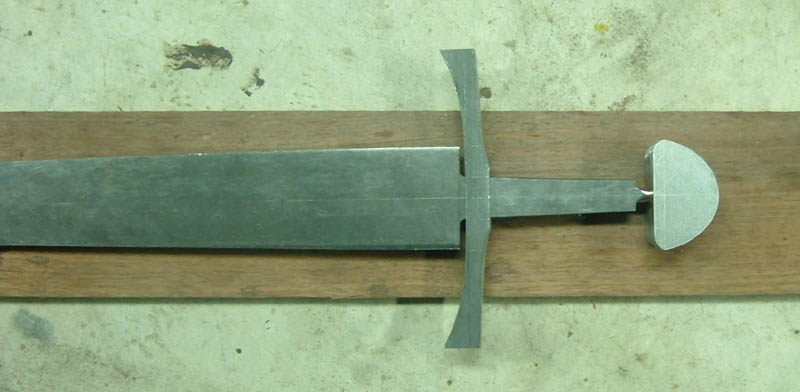

For me, sword making is very much like sculpture, starting with blocks of various materials, and carving them to their final shapes. I'm a carver at heart. Just as an example, here's a couple of shots of a pommel from another project. Starting out from a large chunk of steel, a section was cut off, and ground down to shape it is now in. I'll be posting more about pommels in this thread when it comes time for working on Jean's, but this seemed applicable to the subject.

Mark

Attachment: 26.11 KB Attachment: 26.11 KB

Attachment: 20.1 KB Attachment: 20.1 KB

www.ollinsworddesign.com

|

|

|

|

|

Mark G.

Industry Professional

|

Posted: Tue 09 Jan, 2007 9:24 am Post subject: Posted: Tue 09 Jan, 2007 9:24 am Post subject: |

|

|

Well, the blade has been cut out and profiled on the grinder. That is one massive hunk of steel! I think I'm going to have to reposition my grinder to make sure there's enough clearance all around to work on this blade. It should be fun to grind though, once I get the weight down a bit that is. It's a touch on the heavy side.

To have a bit of fun with the project, we've decided to put together a little "Guess My Weight" (for the steel, not me personally) contest for the profiled blade. Details can be found here:

http://ollinsworddesign.com/osd-contest.html

Mark

Attachment: 14.12 KB Attachment: 14.12 KB

www.ollinsworddesign.com

|

|

|

|

|

Tim Lison

|

Posted: Tue 09 Jan, 2007 12:55 pm Post subject: Posted: Tue 09 Jan, 2007 12:55 pm Post subject: |

|

|

Hey that hex pommel looks familiar.....

|

|

|

|

|

Mark G.

Industry Professional

|

Posted: Tue 09 Jan, 2007 3:13 pm Post subject: Posted: Tue 09 Jan, 2007 3:13 pm Post subject: |

|

|

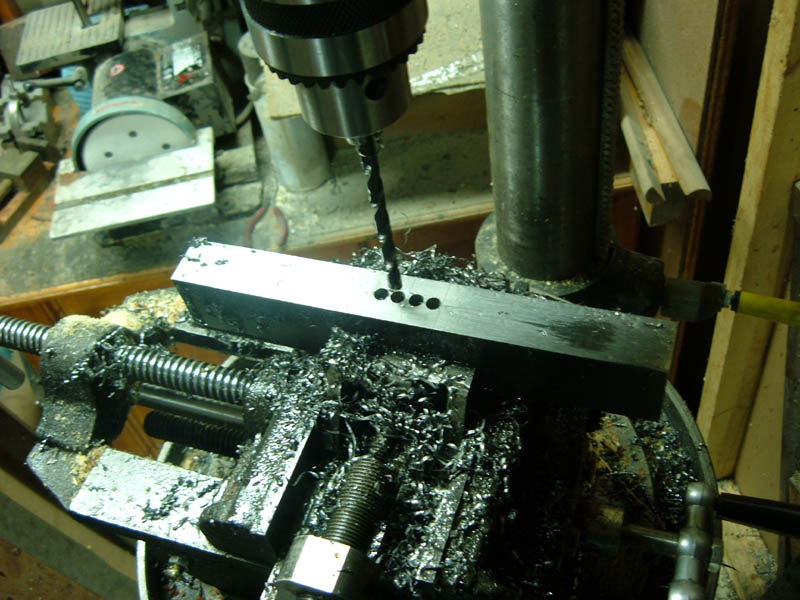

I started in on working on the guard for this piece today.

I'm not sure how detailed of information people are looking for. Basically, I marked out the guard on the piece of steel. Again, the lines are scribed and drawn in marker.

Holes were drilled in the block to remove material for the tang to go through the guard. It's a good idea to drill out slightly smaller than the tang, and then open the hole with filing. That helps with any wandering of the holes, ie they aren't drilled in a straight line.

To save a bit of elbow grease, I cut out the bottom curve of the guard. Otherwise, it would require a heck of a lot more filing to open the hole the entire height of the guard.

Now, it's just a bunch of filing. You can use a round file to take out the webbing between the drilled holes, and once enough of the material is removed, you can switch to a flat file to work the sides flat to where they need to be. Another thing to do would be using a cut-off disc to remove the material. Either way works. I suppose another thing would be using a mill or something, but I don't have one of those.

With the slot in the guard filed out, I can get to work on shaping the top of the guard and bringing everything to rough shape.

Attachment: 44.44 KB Attachment: 44.44 KB

Attachment: 98.81 KB Attachment: 98.81 KB

Attachment: 112.92 KB Attachment: 112.92 KB

Attachment: 91.95 KB Attachment: 91.95 KB

Attachment: 23.17 KB Attachment: 23.17 KB

www.ollinsworddesign.com

|

|

|

|

|

Kenton Spaulding

|

Posted: Tue 09 Jan, 2007 3:22 pm Post subject: Posted: Tue 09 Jan, 2007 3:22 pm Post subject: |

|

|

This is really cool. I am certainly getting a kick out of these updates, and am thankful for the opportunity to watch this come along. Jean, I think you had better get some dumb bells if you don't already have them, and not put them down until this monster arrives. I can't wait to see the further progressions!

Kenton

|

|

|

|

Jean Thibodeau

|

Posted: Tue 09 Jan, 2007 3:46 pm Post subject: Posted: Tue 09 Jan, 2007 3:46 pm Post subject: |

|

|

| Mark G. wrote: | Well, the blade has been cut out and profiled on the grinder. That is one massive hunk of steel! I think I'm going to have to reposition my grinder to make sure there's enough clearance all around to work on this blade. It should be fun to grind though, once I get the weight down a bit that is. It's a touch on the heavy side.

To have a bit of fun with the project, we've decided to put together a little "Guess My Weight" (for the steel, not me personally) contest for the profiled blade. Details can be found here:

http://ollinsworddesign.com/osd-contest.html

Mark |

Strange coincidence as I was trying to figure out how much the cut out blade would weigh and what percentage of that weight would remain ? The objective being somewhere between 5 to 6 pounds final weight for the entire finished sword.

Yes it's going to be heavy no matter what Mark does to it, but the balance and handling should still be good in proportion to it's weight i.e. the good handling of a well designed sword but at 2X or 3X the weight. ( A challenge I would say and I take full responsibility for making the sword this big.  It's an experiment in extreme design I guess and if I wanted a " normal " sword I already have a few of those. It's an experiment in extreme design I guess and if I wanted a " normal " sword I already have a few of those.   ) )

Anyway starting with the uncut blank, them removing material my estimate in percentages: 1) Original blank 100%

2) profile cut remaining weight 60% 3) distal taper+fuller+hollow grinding remaining weight 20% to 33% " wild guess " ?

Once we get the blade down we have to add weight again for the hilt and tweaking the balance.

I won't guess at the actual weight and at the moment and I don't have any " insider information " and as the crazy designer I don't think I should officially participate in the contest on the OlliN site.

If people don't want to " show their cards " I would suggest just talking in percentages rather than actual weight here and go to the OlliN site to participate in the contest.

I'm really curious if my percentage estimates are even close to what the final weight will be.

Oh, and don't forget the contest is about the present weight of the profiled blank I'm more interested on what the final blade weight will be ?

You can easily give up your freedom. You have to fight hard to get it back!

|

|

|

|

|

Mark G.

Industry Professional

|

Posted: Tue 09 Jan, 2007 3:55 pm Post subject: Posted: Tue 09 Jan, 2007 3:55 pm Post subject: |

|

|

I think I'm going to have to work out more than Jean will. By the time he gets it should be manageable, I would think. Right now, it's not very pretty on my end.

And Jean, you can participate the contest as well as anyone else. No one but Matt and myself know the answer, and there can be multiple winners.

Mark

www.ollinsworddesign.com

|

|

|

|

Jean Thibodeau

|

Posted: Tue 09 Jan, 2007 4:00 pm Post subject: Posted: Tue 09 Jan, 2007 4:00 pm Post subject: |

|

|

| Kenton Spaulding wrote: | This is really cool. I am certainly getting a kick out of these updates, and am thankful for the opportunity to watch this come along. Jean, I think you had better get some dumb bells if you don't already have them, and not put them down until this monster arrives. I can't wait to see the further progressions!

Kenton |

Been doing that since 1984 ( Blame the TERMINATOR movie.  ) )

Oh, and I can do a few hammer curl reps ( 3 to 5 ) in semi strict / loose style with an 80 pound dumbbell and a seated concentration curl with a 50 pounder ( Only 1 rep but strict ....... I've been slacking off a bit lately. Oh, I have that 50 pounder right next to me right now on the floor and did one rep to see if I could still do it. )

Still a 5 to 6 pound sword may seem very heavy after a few minutes of holding it, and lifting heavy weights trains more for strength than endurance. ( Well at least I should be able to pick up the sword.    ) )

Note to Mark: I'm really enjoying seeing this progress and I am feeling less guilty about the challenge this is going to be making since you seem to be enjoying doing it.

You can easily give up your freedom. You have to fight hard to get it back!

|

|

|

|

|

Chris Lampe

|

Posted: Tue 09 Jan, 2007 4:01 pm Post subject: Posted: Tue 09 Jan, 2007 4:01 pm Post subject: |

|

|

Mark,

I appreciate you and Jean (as well as the other folks at Ollin) allowing us to follow the progress of this project. As a person with absolutely no knowledge of metalworking and no craftsmanship skills it's quite fascinating to watch the different steps involved in producing a finished sword. What you've shown so far is perfect and more of the same would be great!

Also, I've been very impressed with your work and if I ever get the bug (I've already got a small, nagging itch) to commission a custom project, Ollin will be my first choice.

Keep up the great work!

|

|

|

|

|

Mark G.

Industry Professional

|

Posted: Wed 10 Jan, 2007 8:44 am Post subject: Posted: Wed 10 Jan, 2007 8:44 am Post subject: |

|

|

I enjoy challenges very much. It's what makes work and life interesting. So, there's no need to have any guilty feelings Jean.

I'm glad to see that people seem to like enjoy the progress and evolution of the project. I forgot to mention it, but if anyone has any questions about the process, feel free to ask. I'm happy to share what I can.

Mark

www.ollinsworddesign.com

|

|

|

|

Jean Thibodeau

|

Posted: Wed 10 Jan, 2007 11:04 am Post subject: Posted: Wed 10 Jan, 2007 11:04 am Post subject: |

|

|

| Mark G. wrote: | I enjoy challenges very much. It's what makes work and life interesting. So, there's no need to have any guilty feelings Jean.

I'm glad to see that people seem to like enjoy the progress and evolution of the project. I forgot to mention it, but if anyone has any questions about the process, feel free to ask. I'm happy to share what I can.

Mark |

Well, I'm also in admiration of the skill and steady hands it must take to handgrind the complex grinds I have seen on the swords you have on your site: It's just freaking scary.   ( the word freaking meant in a polite way ! ) ( the word freaking meant in a polite way ! )

I've only done enough hand grinding to be able to appreciate how difficult this can be.

You can easily give up your freedom. You have to fight hard to get it back!

|

|

|

|

|

Mark G.

Industry Professional

|

Posted: Wed 10 Jan, 2007 2:20 pm Post subject: Posted: Wed 10 Jan, 2007 2:20 pm Post subject: |

|

|

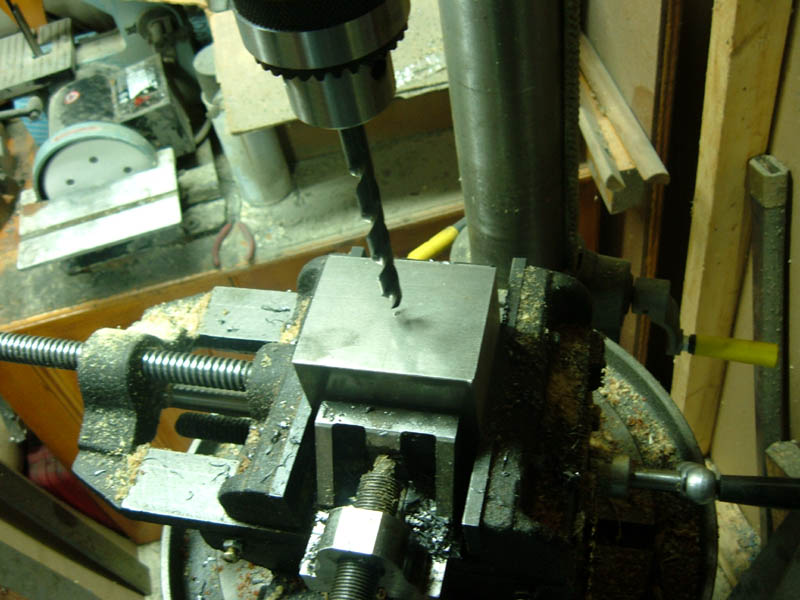

Time for the pommel.

The process is pretty much the same as it was for the guard, cutting out a chunk of metal, drilling a hole, marking out the shape, and cutting/grinding to shape.

I'm sure you all have hard it before, but always double check your measurements. As you can see when I was marking out the shape of the pommel, I originally had the wrong height for it. That would have been a frustrating problem to deal with if I hadn't realized that it looked a little off.

Now the sword is starting to look like something. I just have to do some final assembly, slap on a grip, and it should be good to go. That project went pretty quick....

Jean, I think it might be a good idea for you to really work out. I can barely lift the sword, and even then it's not very much.

Attachment: 85.11 KB Attachment: 85.11 KB

Attachment: 84.57 KB Attachment: 84.57 KB

Attachment: 93.01 KB Attachment: 93.01 KB

Attachment: 26.03 KB Attachment: 26.03 KB

Attachment: 45.16 KB Attachment: 45.16 KB

www.ollinsworddesign.com

|

|

|

|

|

Mark G.

Industry Professional

|

Posted: Wed 10 Jan, 2007 2:24 pm Post subject: Posted: Wed 10 Jan, 2007 2:24 pm Post subject: |

|

|

I took a look at the sword from a slightly different angle, and I think I may have some more shaping to do. Everything seems a touch on the bulky, angular side.

Mark

Attachment: 19.02 KB Attachment: 19.02 KB

www.ollinsworddesign.com

|

|

|

|

Jean Thibodeau

|

Posted: Wed 10 Jan, 2007 4:30 pm Post subject: Posted: Wed 10 Jan, 2007 4:30 pm Post subject: |

|

|

Yup, a little angular but almost finished: Just slap in a handle and it good to go. No need to sharpen it any more.

No need to cut your opponent when you can crush them real good ! ( Sounds like a line from the first Conan movie: Just add the Austrian accent.

Seriously, looks really good.  I just hope my guess about the weight for the contest turns out to be on the lower end of possibilities. I just hope my guess about the weight for the contest turns out to be on the lower end of possibilities.

You can easily give up your freedom. You have to fight hard to get it back!

|

|

|

|

Vincent Le Chevalier

|

Posted: Thu 11 Jan, 2007 1:39 am Post subject: Posted: Thu 11 Jan, 2007 1:39 am Post subject: |

|

|

| Jean Thibodeau wrote: |

Yes it's going to be heavy no matter what Mark does to it, but the balance and handling should still be good in proportion to it's weight i.e. the good handling of a well designed sword but at 2X or 3X the weight. ( A challenge I would say and I take full responsibility for making the sword this big.  It's an experiment in extreme design I guess and if I wanted a " normal " sword I already have a few of those. It's an experiment in extreme design I guess and if I wanted a " normal " sword I already have a few of those.   ) )

|

I'll be very interested in how your future sword will feel in terms of balance...

I tend to consider that weight is not that important for handling but within certain limits of what your body can do. At 2X or 3X the weight of a "normal" sword you are indeed aiming high

The sword, it seems, is also quite a bit longer than usual, which, as far as I understand balance problems, could cause it to be tracking into cuts a bit slower. That's not necessarily something bad, though, as it will give you the time to put power into this beast  Of course that would be true if you were copying the mass distribution of e.g. the sword of St Maurice and just scaling that up, but given your intended center of gravity the outcome could be different... In ways I'll not even try to predict Of course that would be true if you were copying the mass distribution of e.g. the sword of St Maurice and just scaling that up, but given your intended center of gravity the outcome could be different... In ways I'll not even try to predict

Anyway, I'm sure that having your impressions on the handling properties of the final product together with measurements of center of gravity, pivot points, weight, etc. would prove to be a very valuable piece of information to me. I'll definitely appreciate if you could share that later on...

Of course it will also be enlightening to see how Mark works to adjust the balance, and his own appreciation of handling...

Best of luck for this project!

--

Vincent

Ensis Sub Caelo

|

|

|

|

|

|

You cannot post new topics in this forum

You cannot reply to topics in this forum

You cannot edit your posts in this forum

You cannot delete your posts in this forum

You cannot vote in polls in this forum

You cannot attach files in this forum

You can download files in this forum

|

All contents © Copyright 2003-2024 myArmoury.com — All rights reserved

Discussion forums powered by phpBB © The phpBB Group

Switch to the Basic Low-bandwidth Version of the forum

|